Efficient flue gas cleaning is used in modern power stations. A secondary method used to reduce NOx is the SCR (selective catalytic reduction). Thanks to the unique SCR Bypass System from SICK, modern power plants now have a way to actually guarantee the removal efficiency of their systems.

The measuring technique allows operators to control the process and influence the final emission limits at an early stage. In addition, the system can aid in maximizing the run-times of catalytic converters, minimizing ammonia consumption and insuring that the ammonia content of fly ash is kept to a minimum so that it can be used for other purposes.

Simply clever

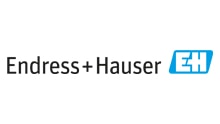

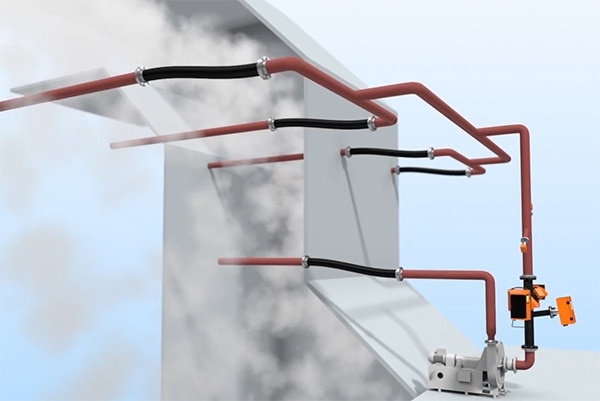

The SCR Bypass System measures NOx in flue gas using a so-called bypass system to achieve a typical gas concentration ‒ a representative sample is taken through specially designed lances with evenly distributed ports. The bypass system with its network of lances is installed in the inlet duct to the SCR and a nearly identical system in the outlet duct. The correct placement and size of the lances is determined in conjunction with the engineering company following their design for the SCR implementation in the plant. The sensors and analyzers take measurements using bypass cuvettes ‒ specially developed by SICK ‒ without distorting any of the results. Gas analyzers and flowmeters from SICK are part of the team of instruments.

The SCR Bypass System measures NOx in flue gas using a so-called bypass system to achieve a typical gas concentration ‒ a representative sample is taken through specially designed lances with evenly distributed ports. The bypass system with its network of lances is installed in the inlet duct to the SCR and a nearly identical system in the outlet duct. The correct placement and size of the lances is determined in conjunction with the engineering company following their design for the SCR implementation in the plant. The sensors and analyzers take measurements using bypass cuvettes ‒ specially developed by SICK ‒ without distorting any of the results. Gas analyzers and flowmeters from SICK are part of the team of instruments.

Control in seconds

The GM32 UV in-situ gas analyzer measures NOx content directly within the bypass cuvette, while the optics of the analyzer are cooled and maintained free of dust using purge air. The measurement result obtained enables the injection of ammonia to be precisely regulated. In addition volumetric flow measurement provides the information to calculate mass flow with FLOWSIC100. The gas mixture is also measured after the SCR. If NOx concentration is still high, ammonia injection is increased. If ammonia level is too high, injection is reduced. The GM700 laser gas analyzer from SICK is an additional unit on the outlet skid that precisely measures the ammonia slip and moisture content.

- Product information: In-situ gas analyzers: GM32 UV, GM700, ZIRKOR302, gas flow measuring devices: FLOWSIC100 H, FLOWSIC100 M-AC

- More solutions from SICK: power stations