Filter by:

667 results:

Mini, easy, speedy

- Small, tried-and tested housing

- High grayscale resolution

- Very large dynamic range means reliable detection of contrasts on glossy materials

- Switching frequency: 10 kHz

- White light

Mobile 1D, 2D and DPM code identification for demanding industrial applications

- Reads 1D, 2D and DPM codes

- Rugged: Survives falls from a height of 3 m and 7,500 impacts from a drop height of 1 m

- Industrial grade: Available with an enclosure rating of IP65 or IP68, suitable for use down to –30 °C

- Easy configuration: By scanning a single barcode, using intuitive software or – during maintenance – by automatic data upload

For universal use with easy adjustment

- Tough metal housing

- Simple sensitivity adjustment in 8 stages

- Bar graph display provides information about the luminescence intensity

- Sensing distances selectable through interchangeable lenses

- Additional optical filters suppress background luminescence

- Fiber-optic cable connection (with 20 mm lens)

- Switching and analog output

The new standard for high-performance luminescence sensors

- Simple teach-in

- Operating range up to 250 mm

- Version with IO-Link for remote monitoring

- Bar graph display provides information about the luminescence intensity

- High speed (6.5 kHz), standard (2.5 kHz), high resolution (500 Hz) models

- Additional optical filters suppress background luminescence

- Fiber-optic cable connection (with 20 mm lens)

- Switching and analog output

Ready for explosive atmospheres

- Certified for use in explosion-hazardous areas in accordance with ATEX, IECEx and NEC thanks to explosion-proof enclosure

- Access protection with differentiation between personnel and materials – without muting

- Hazardous point protection with optional regular blanking

- Available in protective field heights of 600 mm, 900 mm, and 1,200 mm

The safe connection of your programmable device to SICK Remote Service

- Safe remote maintenance connection

- Exact monitoring via maintenance access

- Easy download, configuration and installation

- Seamless integration into existing systems

Accurate part localization for reliable robot handling

- Precise and rapid part localization

- Combined 2D and 3D measurement

- Robot gripper correction calculation

- Web-server-based user interface

- Tools for easy integration with the robot

- Combination of multiple devices possible

One thing is clear - no reflector needed

- Advanced SICK technology

- Elimination of the reflector as an error source

- Machine parts can be used as a reference surface

- AutoAdapt for continuous threshold adaptation in contaminated conditions

- PinPoint LED with bright and precise light spot

- Easy-to-use teach-in pushbutton

- Status LEDs visible from all sides

- Rugged metal housing (PTFE coating available on request)

Powerful detection, smart installation - down to the last detail

- Long sensing ranges: 1,200 mm with background suppression; 15 m on PL80A reflector

- PinPoint LED with bright and precise light spot

- Small housing design

- 10 … 30 VDC or 24 … 240 VAC/VDC power supply with PNP/NPN or relay output

- Rugged sensor housing with metal-reinforced holes for assembly

- Q-Lock assembly system for mounting the sensor within a few seconds

Intelligent, powerful, precise

- High-resolution absolute encoder with up to 30 bits (AFM60) or 18 bits (AFS60)

- Face mount flange, servo flange, blind hollow shaft

- Connection type: 3 x M12 axial plug

- Communication interfaces: PROFINET, EtherNet/IP™, EtherCAT®

- Round axis functionality

- Diagnostic functions

- Status display via 5 LEDs

High performance in a small housing

- Highly accurate camera-based bar code positioning system

- Traversing speeds of up to 7 m/s can be achieved

- Wear and maintenance-free thanks to camera technology

- Adjustable resolution as low as 0.1 mm

- Precise positioning up to 10,000 m

- Compact, extremely rugged magnesium housing

- Wide range of interfaces: SSI, RS-422, and CANopen

- Wide operating temperature range from –30 °C to +60 °C

Enabling switch for safety during setup or maintenance operation

- Plastic housing with connected cable

- 3-stage functional structure (off-on-off)

- Slow-action switching elements with four contacts

- Variant with additional plus/minus buttons

- Complies to the standard IEC/EN 60947-5-8

Reliable turnkey solution for fiscal metering

- Complete calibration is possible

- Customization of instrumentation including gas analyzer, gas chromatograph, and supervisory computer

- Seamless integration with the flow computer Flow-X from SICK

- Available from Class 150 to Class 2500

- Modular design

Modular solutions for fiscal metering

- Utilises the ultrasonic flow meters FLOWSIC600 or FLOWSIC600-XT

- Available from DN 50 to DN 1200 from Class 150 to Class 2500

- With calibration the uncertainty of 0.1% is achievable

- Customization of system components

- Seamless integration with the SICK Flow-X flow computer

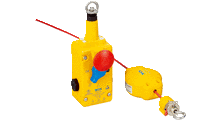

Safe rope pull switch over extra large distances for stopping a machine

- Rope lengths up to 75 m, with rope break and rope pull function

- Metal housing with integrated emergency stop push button and tension display

- Rotary unlocking lever

- Available with M20 X 1.5 cable entry gland or Flexi Loop compatible M12 plug connector (depending on variant)

- Slow-action switching elements with four contacts

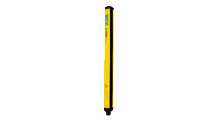

Ready for explosive atmospheres

- Type 4 (IEC 61496), SIL3 (IEC 61508), PL e (EN ISO 13849)

- ATEX II 3G / 3D (2/22 zones)

- ATEX for gas: II 3G Ex nA op is IIC T4 Gc X

- ATEX for dust: II 3D Ex tc IIIC T135 °C Dc

- 7-segment display

- External device monitoring (EDM) and restart interlock

- Beam coding for accurate system allocation

- Configuration and diagnostics via PC

Ready for explosive atmospheres

- ATEX for gas: II 2 G Ex db IIB T6

- ATEX for dust: II 2 D Ex tb IIIC T56°C Db IP6X

- NFPA 70/NEC 500 Class I, Div. 1, Groups C and D

- NFPA 70/NEC 500 Class II, Div. 1, Groups E, F and G

- NFPA 70/NEC 500 Class III, Div. 1

- Available in protective field heights of 600 mm, 900 mm and 1,200 mm

- Resolution of 30 mm

- Scanning range of 16 m

Cuboid inductive safety switch for position monitoring

- Two OSSD safety outputs for direct connection of sensors to a single safety controller

- Response range of up to 20 mm

- LED status indicator

- Up to performance level PL e (EN ISO 13849)

- Flexi Loop-compatible M12 plug connector

Inductive safety switch for position monitoring

- One clocked safety output for direct connection of sensors to a safety controller

- IP67 or IP69K enclosure rating

- Response range up to 15 mm

- LED status indicator

- Up to performance level PL e (EN ISO 13849)

- Safe series connection of sensors possible

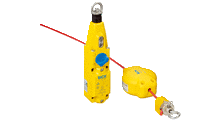

Safe rope pull switch over large distances for stopping a machine

- Rope lengths up to 30 m, with rope break and rope pull function

- Metal housing with integrated rotary unlocking lever and tension display

- Available with M20 X 1.5 cable entry gland or Flexi Loop-compatible M12 plug connector (depending on variant)

- Slow-action switching elements with four contacts

- Complies to the standards EN ISO 13850 and IEC/EN 60947-5-5

Emergency stop pushbutton for fast and reliable stopping of the machine

- Optionally available as a built-in version or as a surface-mounted version with housing

- Built-in version with self-monitoring emergency stop contacts

- Status display with colored mark or LED ring illumination

- Variants with protective collar

- Variants with M12 male connector

Dimensioning with perspective

- Certified measurement accuracy of up to 5 mm x 5 mm x 2 mm (L x W x H)

- Detects object sizes up to 2,600 mm x 1,000 mm x 1,000 mm (L x W x H) depending on system variant

- Conveyor speed of more than 2 m/s possible

- Easy to integrate thanks to MSC800 controller

Easy fieldbus integration

- Flexible mounting on all standard profiles

- Flexible fieldbus connection for PROFIBUS DP, PROFINET and EtherCAT (type-dependent)

- Encoding switch for setting bus address and operating mode (type-dependent)

- LEDs for status and diagnostics

- Plug-in electrical connections

- Integrated parameter memory for connected sensors

- Compact and flexible

The fastest way to visualize safety laser scanner data

- Real-time visualization of protective fields and measurement data on HMIs and PCs

- Read-out and display of the event memory of the safety laser scanner

- Direct access to diagnostic and device information

- For Windows-based SCADA systems (e.g. WinCC from SIEMENS) and Windows PCs

- Supported devices: microScan3 and outdoorScan3