Itella, the Finnish mail and communication company (formerly Finnish Post), has invested in new sorting and detection systems at several parcel sorting centers. As a first in this sector, combined sorting of letters, small packages, parcels and bundles takes place in all of these centers.

The throughput of tote boxes for letters and flats is up to 5,000 units per hour and system. For small packages, parcels and bundled mail, the throughput is 10,000 units per hour for each system. Ensuring such throughput performance technically and at the same time integrating aspects of economic efficiency and invoicing of services rendered is possible only due to sophisticated 1D and 2D code readers featuring integrated imaging for further OCR processing and video coding, as well as legal-for-trade volume measurement systems for the larger containers. All components needed to be integrated into the sorting system via a common control system.

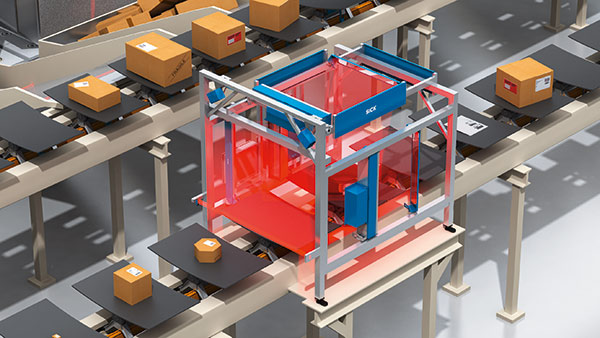

The task was to realize permanent monitoring of the device and system functions as well as the option of remote diagnostics and maintenance from a single source, and to do so together with the overall sensor system combination. Itella decided to acquire the entire technology for the identification, volume measurement, and system monitoring from a single source. The fundamental components of SICKs system combination in each sorting center are the ICR890 camera-based 1D and 2D code readers as well as the VMS520 volume measurement system.

The code readers identify and decode the 1D and 2D codes on the items and send the image data to the subsystems for OCR processing and video coding. The volume measurement systems for precise detection of the height, width, length, and shape of sorting objects are calibrated and legal for trade. In this way, they form the basis for precise invoicing of the services performed.

VMS520 volume measurement system

VMS520 volume measurement system

Each complete system is connected to the system control unit by a controller (MSC800). Use of a tool for monitoring system output and for remote maintenance (RDT400) guarantees the desired availability both of individual components and of the entire systems.

Exact identification of objects and error-free destination control

SICK is the technological leader in the field of identification and volume measurement for sorting systems. By opting for SICK, Itella is not only using the latest future-proof, industry-proven technology; it also received complete solutions from a single source, without any interface risk and with all the components specially adjusted to each other. The uniformity of the solutions also reduced the costs for system tests, implementation, and commissioning. The identification system works impressively well. One could even say it has exceeded our expectations, says Arto Tampio from Itella. The system minimizes units not identified and thus the manual workflow. Thanks to the legal-for-trade volume measurement system, Itella can use the measurement and ID data to invoice services actually performed, even in case of high throughput rates.

- Product information: ICR890 image-based code reader, VMS520 volume measurement system

- Customer information: Itella