One of the first optical linear measurement sensors of its kind to do so, the OLM200 PROFINET from SICK combines maximum functionality and availability with the advantages of control-related integration into PROFINET fieldbus technology. This combination fits very well into the strategy of the automobile industry and of intralogistics.

According to the findings of studies as well as the statements by experts, PROFINET is currently the number one industrial Ethernet protocol in machine and plant building. German car manufacturers, having pushed ahead decisively with PROFINET for years in connection with the Automation Initiative of German Domestic Automobile Manufacturers (AIDA), rely on this communication standard in particular. In recent years, they have probably equipped the robotic and drive systems at every location with thousands of automation systems, sensors, and actuators based on PROFINET. Therefore, equipping the OLM200 linear measurement sensor with an integrated dual port switch for PROFINET represents merely a logical consequence: It makes

the sensor a positioning solution with high future sustainability.

Fast, precise, and reliable: Position detection for straights and curves

OLM200 PROFINET linear measurement sensor

OLM200 PROFINET linear measurement sensor

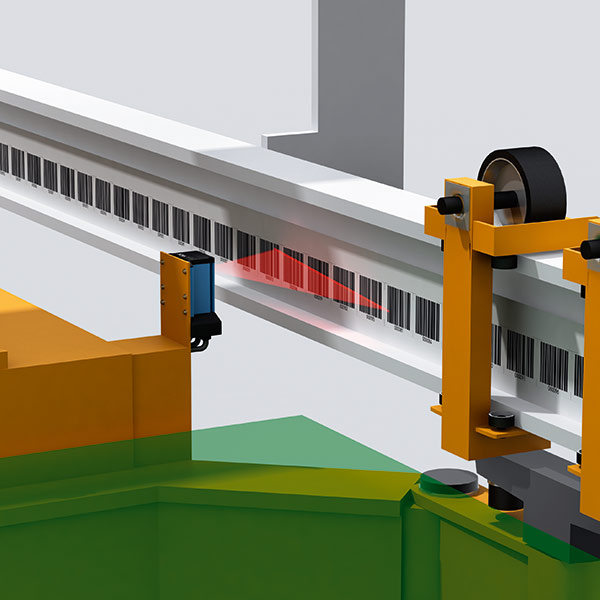

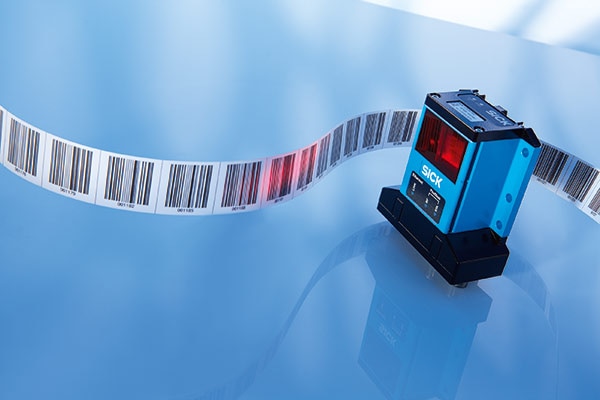

Optical linear sensors of the OLM product family from SICK are used for positioning mobile units. Within the measuring range of up to 10 km, e.g. the length of an electrical overhead conveyor system, the image-processing sensor utilizes a barcode strip for position detection. This process takes place very accurately in case of the OLM200 PROFINET - with a configurable resolution of 0.1 mm and reproducibility of 0.15 mm. In this connection, travel speeds of up to 10 m/s are possible. The camera-based linear measurement sensor featuring a rugged IP65 metal housing manages without any moving components on the inside. This makes the OLM200 PROFINET from SICK highly resistant against shocks and vibrations, and thus fail-safe. For commissioning, it is beneficial that the sensor is capable of independently detecting and processing sensor marks for parameterization and for special functions. Moreover, through corresponding positioning of the camera line on the electronic card, the housing design has taken into account the alignment angles necessary for installation to such an extent that the OLM200 PROFINET requires alignment only in terms of height and distance - without any additional mounting bracket.

OLM200 PROFINET featuring broad range of use

The tasks for the OLM200 PROFINET in plants of the automobile industry and in storage and conveyor technology are extremely diverse: They range from positioning and distancing of overhead conveyors and shuttles to path measurement when moving rotary tables and turntables, and all the way to position detection of storage and retrieval devices that negotiate curves, as well as their lifting axis and load handling attachments. The OLM200 PROFINET stands for precise position detection in the number one communication standard.

- Product information: OLM200 PROFINET linear measurement sensor

- Product portfolio: Linear measurement sensors