For rotation speed measurement and rotor positioning in its slip ring transmitters for wind turbines, the MORGAN REKOFA manufacturing company relies on the wind and weather resistant DFS60 incremental encoders from SICK that can be parameterized freely.

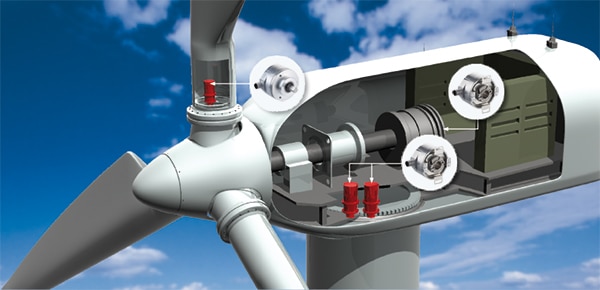

Slip ring transmitters are electromechanical systems for transmitting, among other things, power and data from a stationary to a continuously rotating component, e.g. a rotor of a wind turbine. With the 80A slip ring transmitter, the MORGAN REKOFA Company in Antweiler, Rhineland-Palatinate, an internationally operating manufacturer of rotating transmission systems like these, has developed a solution designed specifically for the requirements of wind turbine builders.

Certainly, these requirements were quite something, as the wind turbines and their components need to guarantee 100 million revolutions and a service life of up to 20 years," Graduate Engineer Oliver Follmann, Design Manager at MORGAN REKOFA, describes the standard set regarding maximum ruggedness and completely maintenance-free operation. He adds: "After all, service in the nacelle is not enjoyable at all, and it may, for instance, on offshore plants, cost several 10,000s of euros."

DFS60: the incremental encoder with the nose to the wind"

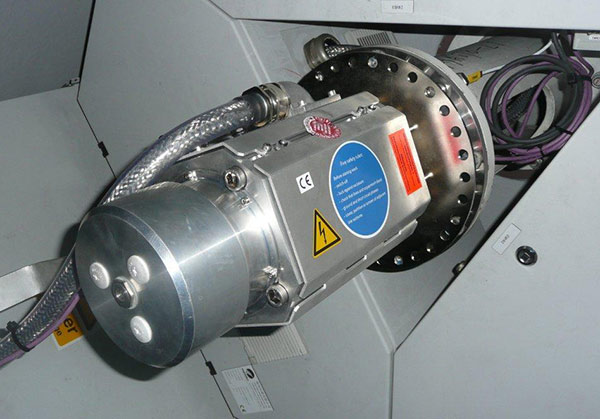

DFS60 incremental encoder[/caption] For rotation speed measurement and rotor positioning, the people at MORGAN REKOFA opted for the DFS60 incremental encoder. Its ruggedness, ability for parameterization even when already installed, as well as first-rate support by SICK in the planning phase and regarding service at a dizzy height in a wind turbine nacelle were the deciding reasons for MORGAN REKOFA. In addition to the IP 65 enclosure rating and the extensive temperature range from -30 °C to +100 °C, the robust and condensation-resistant code disc made of nickel as well as the extended ball bearing distance provide for maximum ruggedness, confirms Roland Höricke from the Design Department at MORGAN REKOFA.

DFS60 incremental encoder[/caption] For rotation speed measurement and rotor positioning, the people at MORGAN REKOFA opted for the DFS60 incremental encoder. Its ruggedness, ability for parameterization even when already installed, as well as first-rate support by SICK in the planning phase and regarding service at a dizzy height in a wind turbine nacelle were the deciding reasons for MORGAN REKOFA. In addition to the IP 65 enclosure rating and the extensive temperature range from -30 °C to +100 °C, the robust and condensation-resistant code disc made of nickel as well as the extended ball bearing distance provide for maximum ruggedness, confirms Roland Höricke from the Design Department at MORGAN REKOFA.

We need only one encoder type for all slip ring transmitters, which benefits procurement, warehousing, designing, commissioning, and servicing. We can set the number of lines flexibly depending on the customer and the plant, even after installation when the encoder is already mounted, says Roland Höricke. This was essential particularly in one case when my colleague, Mr. Follmann, worked on location in a nacelle, requiring him, among other things, to adjust the encoder. Using the PGT-10-S pocket programming tool for the encoder, the task at a dizzy height was solved quickly, he affirms.

From left to right: Roland Höricke, Design Department at MORGAN REKOFA, Klaus Oberkötter, SICK Vertriebs-GmbH, and Oliver Follmann, Design Manager at MORGAN REKOFA

From left to right: Roland Höricke, Design Department at MORGAN REKOFA, Klaus Oberkötter, SICK Vertriebs-GmbH, and Oliver Follmann, Design Manager at MORGAN REKOFA

DFS60: ensuring that there is no "running out of breath"

For MORGAN REKOFA, the DFS60 has become the universal solution for rotary speed measurement and position detection in slip-ring transmission systems. Ruggedness, flexibility, short-term availability even of larger production runs as well as service support by SICK that is possible worldwide make sure the wind turbines do not run out of breath even in continuous operation.

More encoder solutions from SICK for wind turbines:

- Product information: DFS60 incremental encoder, PG-T-10 Display Programming Tool

- Product portfolio: Incremental encoders

- Customer information: MORGAN REKOFA Company