Increasing competition in the process industry means that operations and service work have to be optimized continuously. Also environmental regulations for flaring become stricter. Ultrasonic flow meters have been used for over 30 years to measure flow to flare stacks. Today flare flow measurement is one of the most challenging flow applications since velocities and gas compositions may change rapidly.

Prepared for the future: Ultrasonic flow measurements in flare installations

Flare stacks can be found in many industries as an integral part of the safety and waste gas system as they allow controlled venting for large volumes of combustible components during upset conditions. By their nature, pressure, volume flow, and composition of flare gases can change considerably in short periods of time.

Compact and more optimized production facilities have higher capacities and therefore result in higher maximum flow conditions over the flare. Flow rates of more than 120 m/s have been recorded during shutdown conditions in refineries and petrochemical plants.

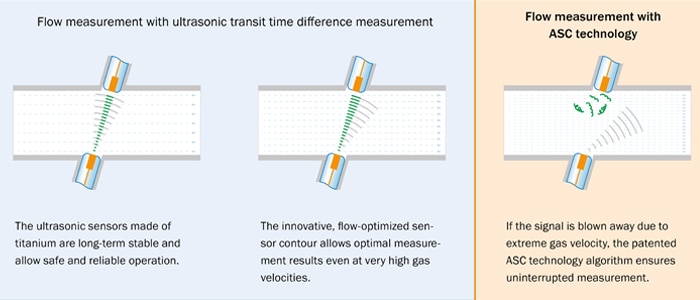

Waste or flare gas can vary greatly in its composition and abrupt flow condition changes should be expected. Furthermore, the low flow conditions became more important for process control and optimization and for identification of valve leakage in normal operational conditions. Minimum flow rates demand highresolution transducer technology and advanced signal processing algorithms to ensure exact time measurement. High flow velocities will introduce soaring noise within the flowing gas when valves etc. are installed before the acoustic ultrasonic measurement. Even drift of the “ultrasonic beam” has to be considered at high gas velocities.

Evolution of global regulatory environment

Environmental regulations are becoming stricter in many industries globally. In the refining, chemical and petrochemical industry, the ultrasonic technology has already been established for many years. Now, increased regulatory pressure and reporting requirements come into play.

This has a strong impact on the need for a reliable flare measurement and data availability – even under difficult conditions. While the regulations for the refining, chemical and petrochemical industry are already defined, we can also see in many other a proactive search for technical solutions to meet future environmental regulations. Especially when it comes to reporting, the Ultrasonic technology offers also here many advantages over other technologies.

Challenges in flare measurement and technological solutions

Ultrasonic flow metering is a well-established technology in fluid metering. Application ranges from custody transfer metering to flare flow measurement or emission control. In principle, ultrasonic flow meters measure the transit time difference with and against the flowing fluid on an acoustic path and conclude the mean flow velocity from this measurement. Here “mean flow velocity” means that the flow velocity averaged over the pipe cross section.

One of the main purposes of flare flow measurement is the exact countability of GHG (greenhouse gas). The focus on accurate GHG measurement increased in recent years. Fees and taxes on air pollution continuously increase. Thus the need for accurate and available measurement increases, too. Dealing with difficult flare gas conditions the requirements for measuring technology pose a challenge in the oil and gas and the chemical and petrochemical industry:

- Gas velocities of 0 m/s to 120 m/s

- Rapid changes in the gas velocity

- Rapidly changing gas mixtures with natural gas, hydrogen, carbon dioxide, etc.

Active Sound Correlation: Reliable even at highest gas velocity

Ensuring measurement availability even at the highest gas velocities is one of the most important characteristics of a flare measurement system. The innovative ASC-technology (active sound correlation technology) is now extending previous maximum flow range by up to 30%. ASC correlates the gas velocity with applicationspecific noise generated at high flow conditions. In this case, the sensor works like microphone. The patented ASC-technology thus allows an even better coverage of possible flare gas events.

Simple maintenance. One-click verification. Self-diagnostics.

Linking software and firmware opens up a lot of new functions and benefits: The self-monitoring system delivers valuable data regarding the device status, shows trends and highlights relevant changes. Application faults are immediately detected and documented; thereby timeconsuming troubleshooting can be omitted. On request, the system verifies itself and records its current status. In this way, users can have a very straightforward means of creating documents that help proving that emission regulations are fulfilled. – all remote and without a service technician to be sent in the field. This reduces operational and safety risks to a large extend.

Self-monitoring systems like i-diagnostics™ support the change from time-based maintenance to condition-based maintenance – leading to reduced number of service intervals and by that reduces maintenance costs.

- Predictive maintenance and flexible Service Intervals:

The system permanently monitors parameters such as the “automatic gain control” or the “signal-to-noise ratio”. Based on existing data and the development of measured values, i-diagnostics™ provides reliable predictions and maintenance recommendations. Systemcritical operating condi-tions are thus avoided – and unplanned downtimes are prevented.

- One-click verification report: instant device verification:

On request, the system checks itself and logs its current status. Users thus have the uncomplicated option of creating verification documents to prove that emission requirements have been met.

- Automatic self-diagnostics:

i-diagnostics™ links software and firmware intelligently: The self-monitoring system provides valuable data on the device status and shows all changes. Application errors are immediately detected and documented – there is no need for lengthy troubleshooting.

The right solution for every challenge

Flare gas meters with ultrasonic technology are used in various applications with different demands, therefore a deep knowledge of the singles challenges is required to offer the right solution. In the refinery industry, for example, current US EPA regulations mandate a minimum combustion zone heating value of 270 BTU/scf. Also, a net heating value dilution parameter of NHVdil ≥ 22 BTU/ft2 for all steam assisted flares is required. All this while maintaining a high combustion efficiency. To meet these requirements and keep the heating temperature on the level needed, Ultrasonic gas flow meters can also be used to control the steam supply.

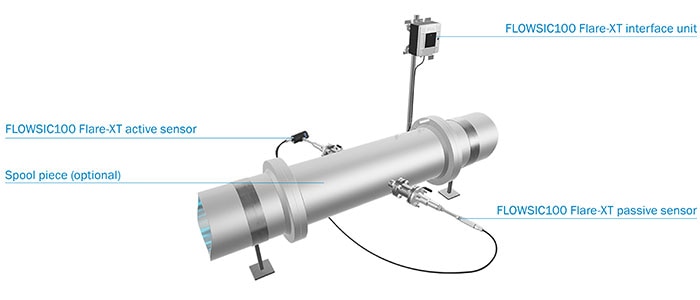

The new FLOWSIC100 Flare-XT flare gas meter is available in three different versions. All versions are available as a 1- or 2-path measurement system. Crossduct installation and single nozzle probe systems are available in either path configuration. The probe version is suitable for compact, one-sided fitting, which minimizes the installation work required. The 2-path version achieves high measurement accuracies even under difficult flow conditions and gives redundancy of measurement. A device-retraction-mechanism also allows sensors to be replaced simply and quickly during plant operation. The powerful interface unit easily connects to a wide variety of systems and networks thanks to its numerous interfaces.

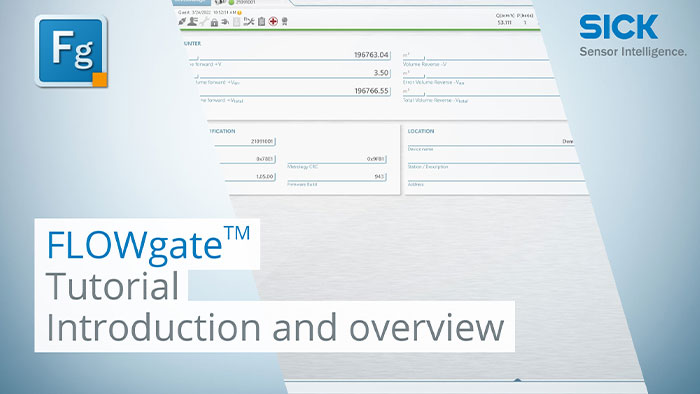

The interface unit processes incoming signals and calculates parameters, such as molecular weight, mass flow and gas volume, as well as standardized reference values. Via an infrared interface, the system can be operated intuitively from a laptop or tablet thanks to the FLOWgate™ software. Integrated Ethernet and RS-485 interfaces allow the device status to be monitored remotely.

Key parameters and measured value data such as volume flow, mass flow or molecular weight are reliably processed, evaluated, and stored. In this respect, the internal memory makes it possible to permanently archive the data in a secure and structured manner. Thanks to interference-free, digital communication, the interface unit can be installed up to 1,000 m away from the measuring point. There is therefore no longer any need for a local, pressure encapsulated, and potentially expensive control unit.

Thermal Mass Measurement Replacement

Some measurement principles, like thermal mass measurement, need clean gas to operate correctly. The ultrasonic technology can overcome fouling or contamination on the Sensors by automatically boosting the signal. This optimizes maintenance intervals, maximizes measurement uptime reduces operating costs. Additionally, Ultrasonic flare gas measurement is the only technology that can operate in a measuring span of up to 1:4000. There is no need to focus on a high or low flow condition as measurement speeds of 0.03 m/s to 120 m/s are possible.

For the demands in upstream, for example, in fracking applications, SICK offers also the FLOWSIC100 Flare-XT Transmitter – reliable and rugged without recalibration. The sensors are directly connected to an already existing flow computer. The interface unit is not needed in this product configuration and neither pressure nor temperature transmitters are necessary.

Individual application evaluation provides specific measurement performance

In flare flow measurement, each application is different: Temperature, pressure, gas matrix, velocity etc. can totally vary. This is why SICK offers an individual application evaluation for each measuring point and searches out the optimal solution. After the evaluation, a Flare gas application evaluation data sheet for each measurement point is provided to the customer – worldwide.