Hermes Schleifmittel in Bad St. Leonhard in the Carinthian region of Austria produces precision abrasives for industry. As a solvent processing company, exhaust gas purification is very important to them from an environmental protection perspective. Optimal (post) combustion of the hydrocarbons used in production is therefore a really important issue for them that is closely linked to the energy costs their incur. A tailored measurement technology-based analyzer solution for VOC measurement (VOC = volatile organic components) was the key to exploiting the significant energy savings potential.

VOC measurement for optimizing the operating costs in the production of abrasives

The manufacturing process for abrasives

The 1.62 meter wide abrasive belts are produced as “continuous rolls”. The starting material is paper rolls that first pass through a stamping machine to print all the necessary product specifications on the reverse side. The belt is then fed through a priming machine that applies the glue. The next process step is performed in a grit application machine. The abrasive grit is electrostatically charged and applied onto the glue-primed belt in the prescribed quantity and distribution. “A work process that requires a high level of accuracy,” explains Michael Hartl, Head Electrical Engineering at Hermes Schleifmittel. “The distribution and granularity are decisive for the grinding result.”

Off to the furnace

“Once the grit has been applied, the belt makes it way to the first drying furnace. There it is fed through the furnace while suspended in loops,” explains Hartl. In the next process step, a top layer of glue is applied to the belt that forms a wear layer and increases the service life of the abrasive. The belt is then dried in another furnace and finally wound up into a “jumbo roll”. During the drying steps, the solvent is expelled from the raw materials used. Strict emission control requirements apply to these gases in Austria. The waste air therefore needs to undergo a purification process. Hermes Schleifmittel in Bad St. Leonhard invested in a modern RTO plant for this purpose. Regenerative thermal oxidation (RTO) is a process for thermal exhaust gas purification and is used in preference for reducing hydrocarbon emissions. At Hermes, the waste heat produced is used, among other things, to heat the company building and supplement the existing wood chip heating system.

Optimized combustion

Michael Hartl: “The hydrocarbon emissions produced depend on the particular product and the point in time in the process. For fine grit there tends to be less pollutants in the exhaust gas, and for coarse grit significantly more. Also, more solvent is emitted at the beginning of the drying process than shortly before the end of the process step. The quantity of emissions in the exhaust gas – i.e. the concentration – is decisive, however. Without a metrological analysis of the VOC concentration, you would need to always feed the maximum waste air quantity to the exhaust gas purification system, perhaps also from production areas in which no production/drying occurs. “Clean” waste air that does not actually need post-combustion would therefore also be introduced into the RTO plant.” That results in an unnecessarily high energy usage for operating the fans. There is also another crucial factor to consider: If there are less flammable hydrocarbons in the exhaust gas, the post-combustion unit requires more supplementary fuel in the form of natural gas. It is also important to know how high the pollutant concentration is in the waste air coming from the drying furnaces in order to optimize the exhaust gas purification system with regard to operating costs.

Goal: autothermal operation

“Previously, all waste air from production was subjected to post-combustion treatment with a view to complying with the air pollution control regulations at all times. This put us on the safe side,” explains Michael Hartl. But the resultant use of operating resources is unnecessarily high, however. When the concentration of solvent in the exhaust gas is high, the regenerative post-combustion unit does not require any additional fuel. This is referred to as autothermal operation. In this case the exhaust gas contains sufficient flammable solvent vapors that the pollutants can be oxidized without adding primary energy (for example natural gas). The plant heats itself using the energy released in the oxidation of the pollutants. At maximum extraction capacity, this state is not achieved. “If you know the concentration of the volatile hydrocarbons in the waste air, then you can control the extraction system so the post-combustion unit operates at close to optimum, which is autothermal operation. If the waste air is extracted in a targeted manner from those areas where production is currently in progress, the concentration of hydrocarbons increases and the amount of natural gas required decreases.

Complex measurement method

Given the current concern for the environment and rapidly rising energy costs, more and more operators are considering measuring volatile hydrogens (VOCs). This requires a complex measurement procedure, however. For this you need the right metrological solution and a lot of implementation knowledge – which is what Hermes Schleifmittel found with the experts from SICK. “It was a real partnership of equals,” emphasizes Michael Hartl. “This type of measurement was new ground for us. It is very dependent on the specific production processes – a ‘one size fits all’ solution would simply not suit.”

Switching between different exhaust gas streams

“We wanted a complete solution from a single-source partner. So the aim was to combine our knowledge of abrasives manufacturing and the solvent usage required for this with the expertise of a specialist company in the area of process analytics. The experts at SICK helped us develop the most efficient possible analysis solution and pointed out to us that instead of using three individual measurement systems, we actually just needed to switch between three different sampling points,” explains the head of electrical engineering at Hermes Schleifmittel. Drying is seldom performed in all zones of production at the same time. That gave us the idea to automatically switch the sample gas collection between the three possible waste air streams.

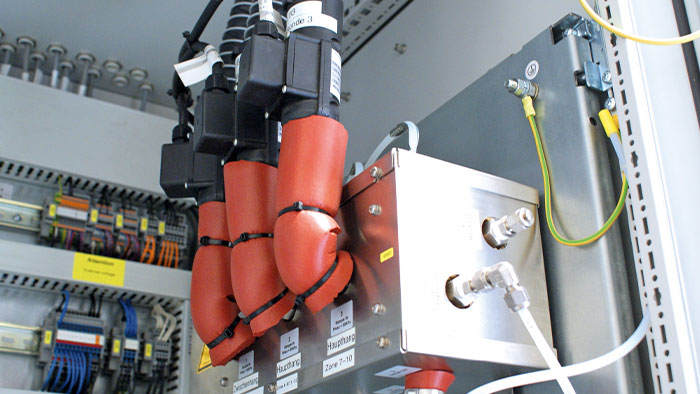

Heated sample gas lines prevent condensation

Another important component of the solution: The volatile hydrocarbons are conveyed through heated sample gas lines to prevent condensate from forming due to cooling, which can then collect in the lines and block them. Michael Hartl: “Thanks to the heated sample gas lines from the sample gas collection point to the gas analysis, condensation effects are avoided and it is possible to perform reliable and long-term stable analyses. The advice we received from SICK definitely paid off: The entire measurement system has been running for three years now without any problems and the reduction in energy usage has been appreciable.”

Savings that pay off

Michael Hartl is happy with the success they have had with VOC measurement: “As a matter of fact, we have been able to significantly reduce our natural gas usage. The amount of natural gas we need to add when manufacturing some products has been reduced from 50 m3/h to 30, 20 or even 10 m3/h. That is substantial, and has even exceeded our expectations!“