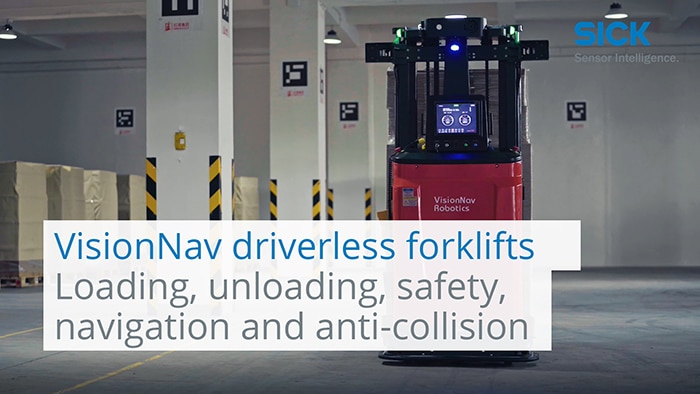

Logistics automation is on the rise. Whether due to digital transformation, the global pandemic, or the general focus on a higher degree of automation – intelligent intralogistics is turning into more than just a trend. A crucial factor here is state-of-the-art automated guided vehicle solutions. To meet the diverse challenges of transporting goods, VisionNav Robotics, a global provider of autonomous vehicles, and SICK are providing a whole range of joint solutions.

Automation in intralogistics: Perfecting the automated forklift truck

The combination of VisionNav Robotics forklift technology with intelligent sensor technology plus the many years of experience of SICK enables the use of forklift trucks in demanding environments, such as automatic navigation, safe and effective avoidance of obstacles or shelf detection, to name a few examples.

The various sensor solutions for the forklift truck: for safety and efficiency in operation

But how exactly do these sensors on the forklift truck work? What new applications are possible for the forklift truck? The video shows how the sensor solutions used in very different places for different tasks ensure safe and highly efficient operation of the forklift trucks:

The TiM351 2D LiDAR sensor is used in the VNE20 counterbalanced truck for indoor and outdoor use, which does loading work. It ensures reliable avoidance of obstacle, thereby increasing safety, especially in demanding environments.

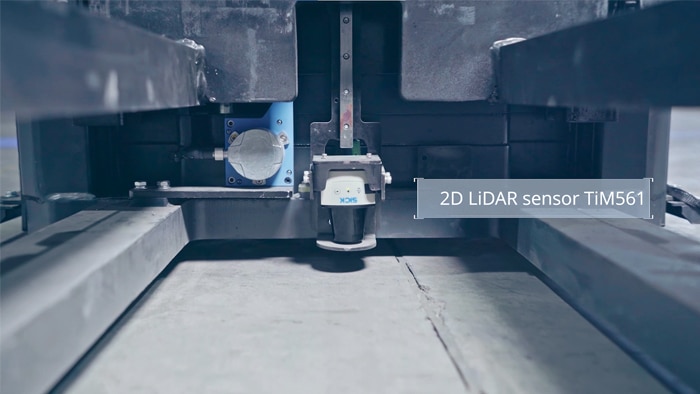

The TiM561 2D LiDAR sensor is used in the VNP15 automated counterbalanced truck for mesh box transport in warehouses with limited space. This ensures that the position of the pallets is accurately detected and that the forks of the truck are correctly inserted into the pallet.

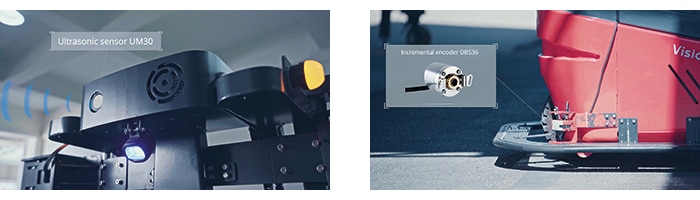

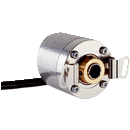

VisionNav Robotics uses the PFG19 wire draw encoder in the VNR14 automated reach truck for access to shelves in high-bay warehouses; this encoder allows the truck to monitor the lift height of the forks in real time. At the same time, a Dx35 mid-range distance sensor is used to measure the sideshift of the forks and control it with millimeter precision. The UM30 ultrasonic sensor controls the forklift’s height protection function, and an inductive proximity sensor (IME) helps detect target positions. Finally, the DBS36/50 incremental encoder measures the angle of the drive unit on the wheel of the forklift.

If CE marking of the automated forklift truck is required, the nanoScan3 safety laser scanner with the Flexi Soft safety controller ensures the vehicle and its surroundings are safe.

Higher storage capacity and reduction of damage in the warehouse

This is how sensor solutions from SICK guarantee that automated forklift trucks perform their tasks reliably, thereby increasing efficiency and safety in different logistics operations. This leads to a higher storage capacity and at the same time to a significant reduction in goods damage in the warehouse. Logistics automation continues to advance – and with it the two partners VisionNav Robotics and SICK.

About VisionNav Robotics

VisionNav Robotics was co-founded by a team of PhD students at the Chinese University of Hong Kong. The company focuses on the application of key technologies such as artificial intelligence, environment awareness, deep learning or servo control in the field of autonomous driving in industry. VisionNav offers automated vehicles and flexible autonomous logistics solutions for production lines and warehouse logistics.

Read more

Hybrid approaches increase efficiency in production and logistics

Autonomous intralogistics from indoors to outdoors: SICK and Stäubli WFT provide a seamless logistics chain for BASF

Greater autonomy thanks to modular vehicle fleet: Seamless indoor and outdoor operation in intralogistics

Jungheinrich automates lift trucks: higher throughput through agile cornering and safety