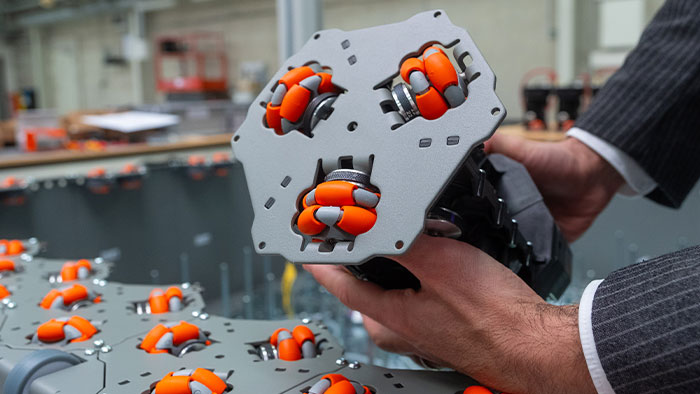

In Northern Germany, they have literally turned the robot world on its head and created an outstanding material flow solution. The idea from cellumation in Bremen: Combining autonomous football robots into a unit – and then turning the whole thing upside down. The ingenious thing about it: Instead of chasing the ball around freely on a surface using an assembly of three drives in a triangular arrangement, flipping it over allows goods to move freely on a surface. The moves of the individual players – a team effort of sorts – enable a maximally flexible routing of goods of any kind. 3D vision cameras from SICK provide the necessary overview from the sidelines.

The logistics playing field in focus: how a 3D vision camera optimizes the material flow

There is a market for an intelligent material flow, but it needs to satisfy two things: high-performance movement control combined with minimal space requirements: “The floor space for logistics is shrinking and the acceptance of shared spaces falling - in particular due to the low value adding per square meter,” describes Theresa Gröninger in regard to the declining push for new logistics centers at the edges of towns. This development is countered, however, by the ongoing high volume of orders from consumers. This dilemma has lead to a demand for more effective material flow solutions. The objective is simply to deliver more conveying capacity in a smaller space. “That's where our modularly designed and therefore easily scalable celluveyor comes in,” says the marketing manager of the company that was founded in 2017.

3D images for the routing on the surface

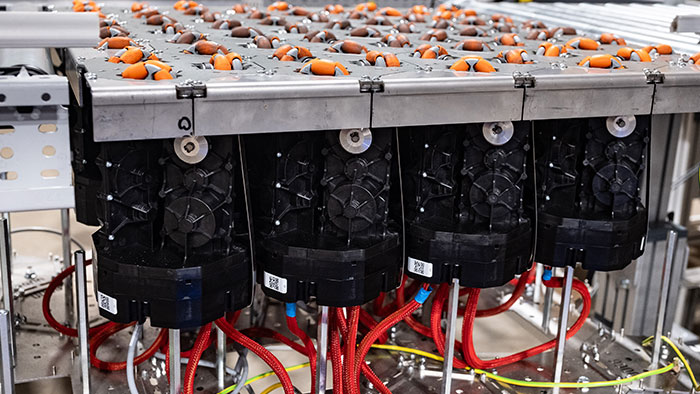

The upside down team of robots forms a honeycomb-shaped transport system. How many units are combined into a whole for a particular application depends on the conveying task, the required capacity, and the weight of the packaging units. To ensure the individually configurable modules retain a high degree of standardization, cellumation offers the individual players in just two size and capacity variants. In terms of layout, they are designed for cell spacings of 150 and 200 mm. The larger units are designed to cater for larger packages thereby limiting the number of cells per unit area. What remains the same in both cases is the entire control technology, including the connection to the Visionary-T Mini 3D time-of-flight cameras from SICK.

The special feature of this 3D method is that the spatial vision is produced using time-of-flight technology. The camera therefore does not require two lenses, as is customary for so-called stereoscopy as well as human vision. Instead, the Visionary-T Mini measures on every point of an object the time for the infrared light of the camera to travel from the source to the object and - after reflection - back again. With these time values obtained from a single snapshot, the computational intelligence of the camera forms a 3D point cloud using which objects can be captured in three-dimensional space. The 3D data provide reliable information on the size and position of an object at a very specific point in time. This level of detail is what distinguishes this method from the operating principle of 3D laser scanners, which create an image line-by-line.

Initial research with cameras for toys

For cellumation, this method was decisive for controlling movements on the table of the celluveyor. “3D scanners actually have a problem with moving objects,” explains Claudio Uriarte, who founded the company in 2017 together with Dr. Hendrik Thamer. Both scientists were working for the Bremen Institute for Production and Logistics (BIBA) at the time. Their scientific work at BIBA – a company that belongs to the University of Bremen – involved intralogistics-related research and the search for solutions for the autonomous unloading of containers. “We initially used 3D LiDAR sensors from SICK,” recalls Claudio Uriarte. Then true 3D cameras came on the market, but they were built into game consoles. “We did a lot of work and testing with the cameras. This left us with a desire for a rugged solution for industrial use.” The two scientists stumbled across the new Visionary cameras with their 3D snapshot technology in the traditional manner through a press release. That was the beginning of an intensive collaboration with SICK at a project level.

Images free of artifacts

But why the long search for an industrial grade 3D camera when suitable scanners already existed? There was still the briefly mentioned problem of how these scanners handle moving objects – and there are plenty of these in intralogistics. Claudio Uriarte speaks here of a tail that the laser scanners with their line-by-line scanning leave behind when objects are not at rest. The “motion artifacts” are like a trailing ghost. With the Visionary-T Mini, however, these artifacts are not present and a clear image is obtained due to the single, brief exposure: the 3D snapshot. “This gives us up to 30 images per second. The data is free of blurriness and enables us to precisely control movements.” In this setup, the Visionary-T Mini therefore serves as a quick feedback mechanism for the purposes of obtaining a fast and closed control loop.

30 images per second, and each as a three-dimensional point cloud: To ensure this measurement procedure does not lead to unmanageable data volumes, the SICK camera performs some pre-processing which is then converted into position data by the controller of the celluveyor. According to Claudio Uriarte, it is helpful that the point cloud of 3D coordinates delivered by the camera can be readily segmented. “We can clearly distinguish what data belongs to a parcel, and what belongs to the stationary table. In the post-processing we can then cut out everything that is irrelevant for movement control.”

And they all move at the same time

The Bremen company has integrated the cameras directly above the distribution table. If an intralogistics application requires a larger dimensioned module, cellumation uses a combination of cameras to ensure there are no blind spots on the line when monitoring parcel movements. This constant support from the 3D eye is necessary because there is no fixed routing on the celluveyor. The controller of the unit continuously recalculates the ideal connection between the entry and exit points based on the supplied actual positions. In this way, the celluveyor can process several parcels at the same time and even next to each other. This characteristic is what leads to the stated performance of the system. Another advantage: Unforeseeable movements of a parcel due to varying weights or the haptics of the packaging material do not affect the process. If an item deviates from the originally calculated route, this is not an issue for its subsequent transport. The reason: The controller simply recalculates the path based on the actual position supplied by the Visionary-T Mini. This method represents a true innovation and effectively prevents parcels from colliding or jamming. This in turn makes the material flow in intralogistics a good bit more reliable and improves the overall system availability.

With this setup of individual drive modules and 3D camera technology, cellumation has succeeded in constructing a true racehorse for intralogistics. “We are ideally used in applications that require decisions in routing. We are an ideal supplement, for example, to stationary belt or roller conveyors,” describes Theresa Gröninger in regard to market potential. Thanks to its ease of integration, the solution from Bremen can also be used to improve the productivity and flexibility of existing systems as part of a retrofit.

The technology was recently awarded the “Innovation Prize Logistics” 2024 by the VDI Society for Production and Logistics. The prize is awarded to companies that have made an outstanding contribution to innovation in logistics.