- 시작 페이지

- RFID Know-How: Identification using RFID technology

- 시작 페이지

- RFID Know-How: Identification using RFID technology

Contents

Frequently asked questions regarding RFID (FAQ)

-

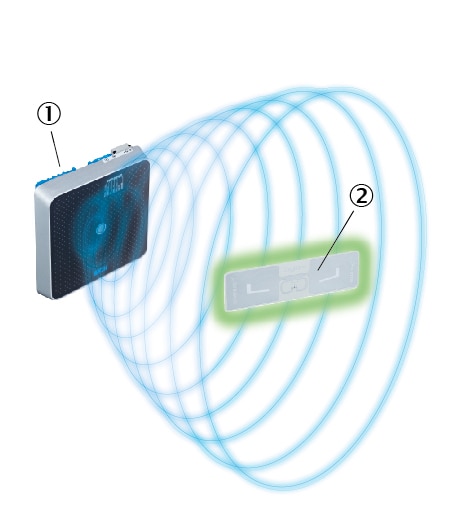

What is RFID?

Radio Frequency Identification (RFID) is a technology that uses radio waves to automatically identify objects.

It is based on an RFID system, which comprises an RFID reader (1) and an RFID transponder (2).

The transponder is located directly on the object to be identified, while the RFID reader contactlessly reads the data stored on the transponder from some distance away.

RFID system

RFID system- 1) RFID reader

- 2) RFID transponder

The transponder types are divided into three categories according to the type of data transmission:

Passive RFID transponders use the energy from the electromagnetic field of the RFID reader to receive or send data.

Semi-passive RFID transponders use a small integrated battery to supply additional energy to the chip in the transponder. This enables the transponder to also be used over larger sensing ranges.

Active RFID transponders have a battery that enables them to continuously record and save measurement data (temperature, moisture etc.). The saved measurement data can, when necessary, be read using the RFID reader. This eliminates the expense of a permanent radio connection to the transponder.

Passive & semi-passive Active Advantage - Low purchase costs - Higher sensing ranges

- Continuous recording of measurement data possibleDisadvantage - Lower sensing ranges - Maintenance costs due to replacement of the batteries

- Higher purchase costs -

What are the advantages of RFID?

RFID technology can fundamentally be described as a “fault tolerant” and very flexible identification technology. Identifying an object requires neither a precise laser line nor consideration of the depth of field.

The most important benefits at a glance:

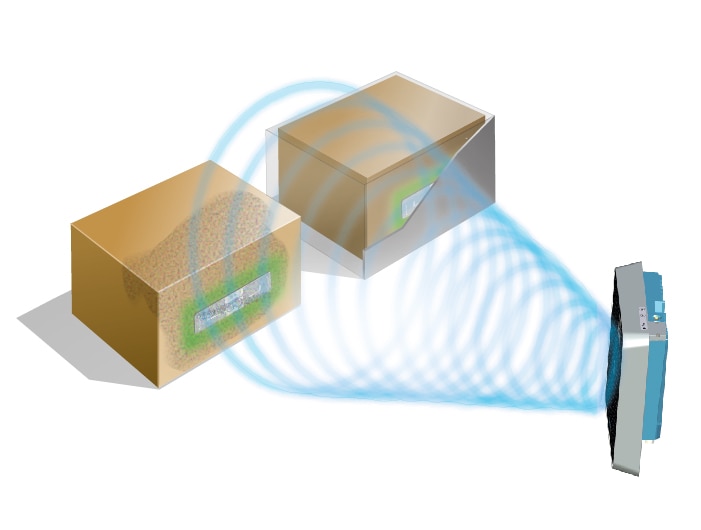

Using RFID technology, it is possible to identify objects without a direct line of sight from the RFID read/write device to the transponder.

This enables even heavily contaminated objects and RFID transponders to be identified, which makes it possible to use RFID technology in challenging ambient conditions.

Objects that are packaged, located in a transport box, or installed in another object can be identified.

Furthermore, the alignment of the object, for example on a conveyor belt, is not a crucial factor, as is the case with optical identification systems. The object can also be identified if the transponder is located on the opposite side to the RFID reader.

This lack of dependence on the alignment of the RFID transponder and the RFID reader provides more flexibility in how the transponder can be attached to the object and how the object is aligned with the RFID reader.

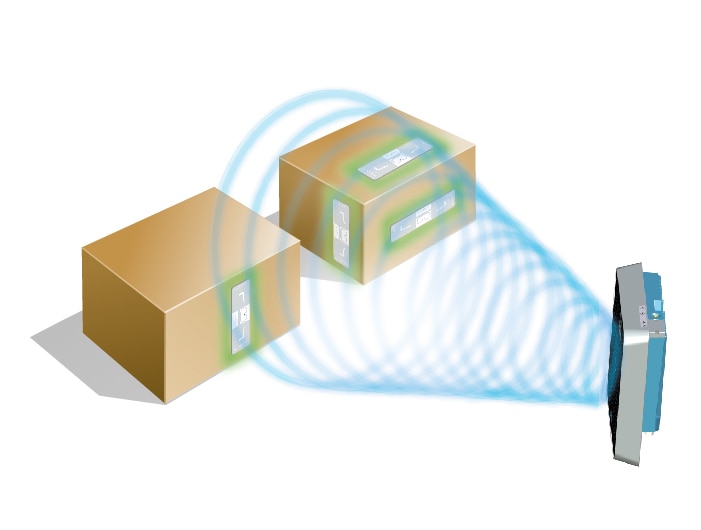

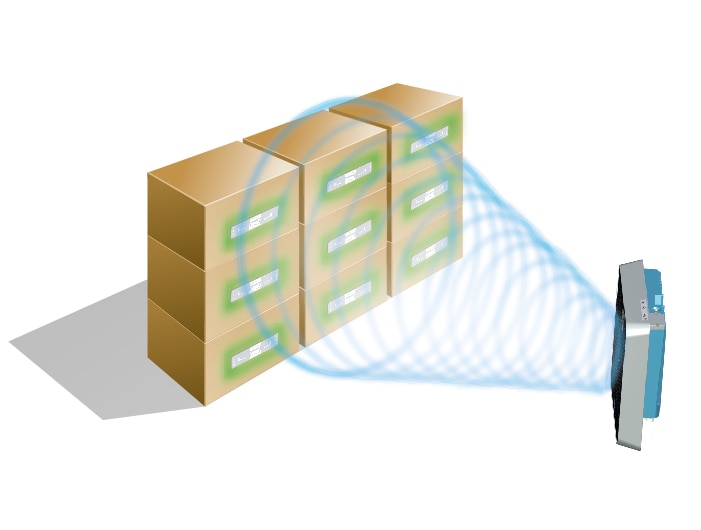

Using RFID technology, hundreds of transponders per second can be identified simultaneously (bulk reading).

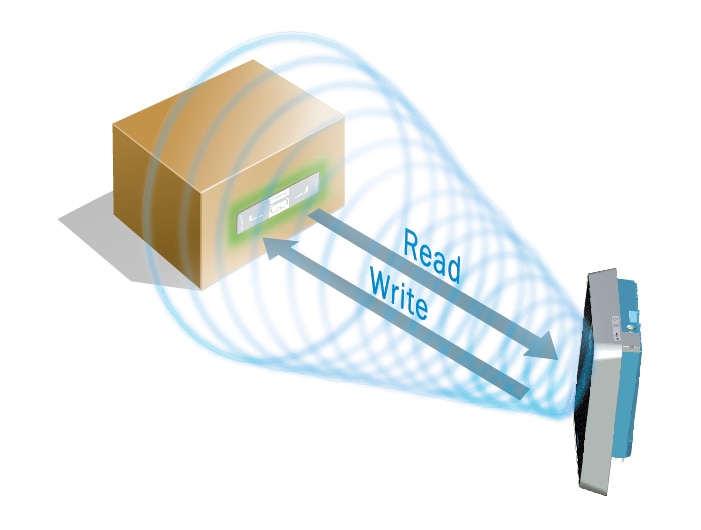

Using RFID technology, the information in a transponder can not only be read but also modified or rewritten. This occurs directly within the process and enables additional (process) information to be stored directly on the chip of the object being identified.

RFID technology makes it possible to reliably identify objects both over short and long distances (up to 10 m).

RFID allows large quantities of data (up to 64,000 bits) to be transmitted and stored on the transponders.

Compared to optical identification solutions, a further advantage of RFID technology is that a reader can solve a wide variety of applications. It can do so without requiring any mechanical modifications such as special optics, illumination units or lenses.

Furthermore, the size of the reading field can be flexibly tailored to the specific requirements by means of software settings.

Below is a list of further advantages of RFID compared to optical identification technologies:

Identification technology

RFID

Optical

HF

UHF

Image-based code readers

Bar code scanner

Short range (< 0,5 m)

√

√

√

√

Mid range (0.5 m … 2 m)

X

√

√

√

Long range (> 5 m)

X

√

X

X

Omnidirectional reading

√

√

√ (in one plane)

X

No direct line of sight required

√

√

X

X

Immune to ambient influences

√

√

X

X

Maintenance-free

√

√

X

X

Bulk reading

X

√

X

X

Rewritable

√

√

X

X

Data cards

Price

Versatility (form factor, materials, etc.)

~ € 0.10 - € 20

Average

~ € 0.05 - € 20

Very high

< 0,01 €

Very high< 0,01 €

Very high -

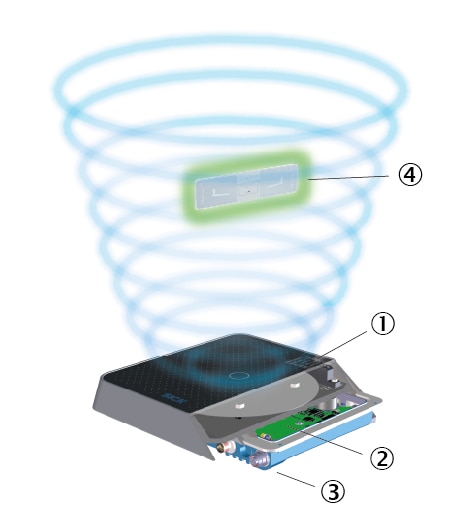

What is an RFID reader?

An RFID reader (also: RFID read/write device) has an antenna that sends requests to the RFID transponder and receives data from it.

The RFID reader also has the ability to evaluate the received data and decode it into the desired target format. Lastly, the RFID reader has various interfaces that enable the data to be forwarded to the desired target system (computer, controller, cloud, etc.)

Components of an RFID reader with integrated antenna

Components of an RFID reader with integrated antenna- 1) Antenna

- 2) Data evaluation

- 3) Interfaces

- 4) RFID transponder

-

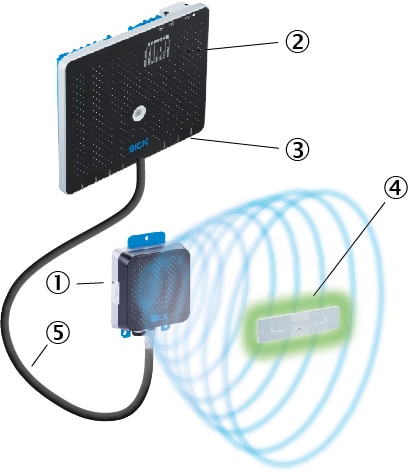

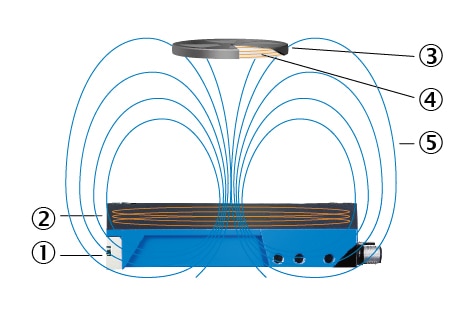

What is an RFID antenna?

An RFID antenna is a mechanical component that regulates the emission and reception of an electromagnetic field.

The antenna enables the chip of the RFID transponder to send identification information to an RFID reader or to receive requests.

The antenna can either be directly integrated into the RFID reader (integrated antenna) or be separate from the RFID reader and connected via a lead (external antenna).

RFID reader with external RFID antenna

RFID reader with external RFID antenna- 1) External RFID antenna

- 2) Evaluation unit

- 3) Connectivity

- 4) RFID transponder

- 5) Antenna lead

-

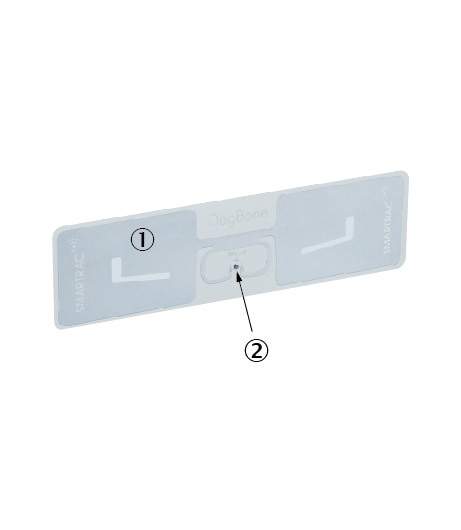

What is an RFID transponder?

An RFID transponder (also: RFID tag) comprises an antenna and a chip (also: IC, Integrated Circuit).

The chip controls the communication with the RFID reader and serves as a memory bank for the relevant data (up to 64,000 bits) necessary to identify the object.

Components of a transponder

Components of a transponder- 1) External RFID antenna

- 2) Chip (IC)

-

What is an RFID system?

An RFID system essentially comprises an RFID reader and an RFID transponder. Depending on the specific use, further sensors, mechanics or even software may be required to solve more complex applications. So-called system solutions are often required to enable several 100 transponders to be read simultaneously (= bulk reading). These system solutions may fulfill the following additional functions:

- Triggering

- Assignment algorithms

- Customized engineering (e.g., shielding)

- Software integration (ERP, MES etc.)

Typical applications include:

Components of an RFID system solution

Components of an RFID system solution- 1) Shielding

- 2) RFID reader

- 3) Antennas

- 4) Triggering and direction detection

- 5) Software and algorithms

-

What RFID frequency ranges are there?

RFID technology can be grouped into three frequency ranges.

LF RFID HF RFID UHF RFID Frequency < 135 kHz 13.56 MHz 865 MHz ... 928 MHz Sensing range < 0,1 m < 0,3 m < 10 m Standards ISO11784, ISO11785

(Animal identification)

since 1994Note: Is not offered by SICK.

ISO14443 (since 2000)

Note: Is not offered by SICK.

ISO15693 (since 2001)

ISO18000-63 (since 2004) Transmission principle Inductive coupling, load modulation Inductive coupling, load modulation Capacitive coupling, backscatter Typical applications Access control, time tracking, animal identification, vehicle immobilization Cashless payment, ticketing, workpiece carrier identification, library Textiles and clothing, vehicle identification, baggage tracking, pallet identification Data standards - - Automotive: VDA (container management, tracking of parts and assemblies, vehicle distribution)

Aviation: IATA (baggage tracking)

Transport, rail: NetworkRail, SJ, SBB, ProRail (Automatic Vehicle Identification)

GS1: open supply chains, shipping containers in logistics, inventory management, reusable containersUse Closed loop (company-internal use) Closed loop (company-internal use) Open loop (intercompany use) SICK products - RFH62x, RFH5xx, RFID transponders, RFID antennas RFU61x, RFU62x, RFU63x, RFU65x, RFID transponders, RFID antennas, RFGS Pro, RFMS Pro -

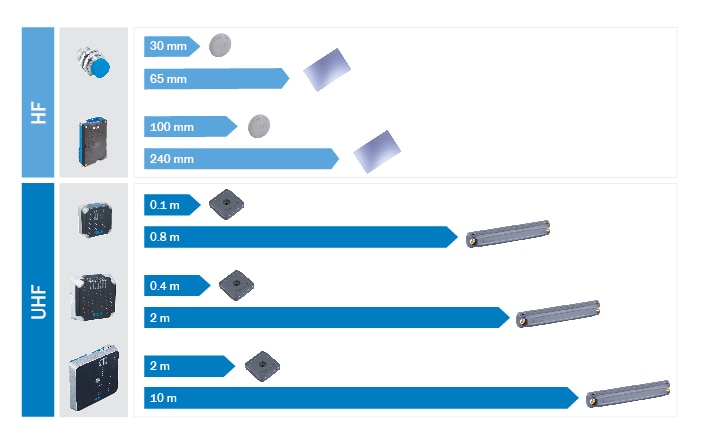

What is the sensing range of RFID?

The sensing range of an RFID system depends on numerous factors. These include the frequency of the RFID reader, the RFID transponder used and its chip, the alignment of the tag and the reader, as well as ambient influences.

Different sensing ranges can be achieved depending on the frequency used for an RFID system.

- LF RFID: up to 0.1 m

- HF RFID: up to 0.3 m

- UHF RFID: up to 10 m

The choice of RFID transponder greatly affects the achievable read range. In general it can be said that the larger the antenna surface area, the larger the sensing range.

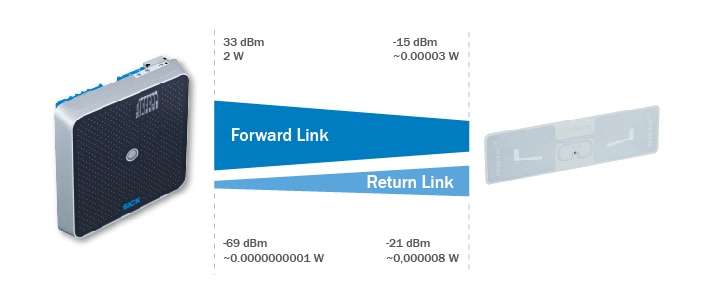

The chip in the RFID transponder is also decisive. Chips have become significantly more sensitive in recent years. As a result, they require less energy from the RFID reader to receive data (forward link) or send data (return link).

Sensing ranges of up to 100 m can be achieved for RFID systems with active transponders.

A further factor is the alignment of the RFID tag and the RFID reader. An optimal alignment of the RFID transponder can improve the sensing range enormously, whereas a suboptimal alignment can result in a significantly reduced sensing range.

A further influencing factor is the immediate environment in which the RFID system is employed. Certain materials such as metal, the temperature, or liquids can affect the sensing range.

We generally recommend carrying out some tests to ensure that a particular combination of transponder and reader functions in a specific application.

-

How does RFID work?

The so-called air interface refers to the transmission of data via the medium of air by means of electromagnetic waves. The transmission method of the air interface (reader ↔ transponder) differs between LF/HF RFID and UHF RFID.

LF/HF RFID

LF and HF RFID operate on the principle of inductive coupling, whereby the antenna coil of the RFID reader generates an electromagnetic field. When an RFID transponder is located in this field, a current is induced in the antenna coil of the transponder thereby supplying the transponder with energy. The current is temporally damped by the circuits in the chip which generates a signal. The RFID reader detects the change in the field and derives a digital signal from it.

HF RFID – inductive coupling

HF RFID – inductive coupling- 1) RFID reader

- 2) RFID reader antenna coil

- 3) RFID transponder

- 4) RFID transponder antenna coil

- 5) Field lines

UHF RFID

UHF RFID operates on the principle of capacitive coupling and uses the so-called backscatter method. The antenna of the RFID reader generates an electromagnetic field that induces a current in the antenna of the transponder thereby supplying the transponder with energy. The thereby activated chip of the transponder modulates the carrier signal, which in turn is received and evaluated by the reader.

UHF RFID – backscatter method

UHF RFID – backscatter method- 1) RFID reader

- 2) RFID transponder

- 3) Electromagnetic field from the reader – forward link

- 4) Signal from the transponder – return link

-

How much does RFID cost?

RFID readers are generally cheaper than comparable optical identification sensors because they have no moving parts for focus adjustment, laser diodes or optical lenses. Industrial RFID readers start at a list price of approx. 800 euros.

The price of RFID transponders has dropped enormously in recent years. Simple RFID transponders are now available for a few cents when purchased in bulk. Even more elaborate transponders that can also withstand high temperatures and rugged environments are relatively cheap and cost just a few euros each.

-

What needs to be taken into consideration when setting up an RFID system?

When setting up an RFID system, there are a few basic requirements that need to be considered:

- Data storage concept

- Will data only be read and the RFID number linked to a database, for example using bar codes (→ “data on system”)

- Will new data (repeatedly) be written to the tag (→ “data on tag”)?

- When and by what means will a read/write operation be triggered?

- RFID reader reads/writes constantly

- RFID reader reads/writes on request (e.g., command from a controller or signal from a photoelectric sensor)

- Data output: What information apart from tag data are of interest (time, location, RSSI value, etc.)?

- Connection to the HOST system: interface (fieldbus, IT system), protocol

Additional factors:

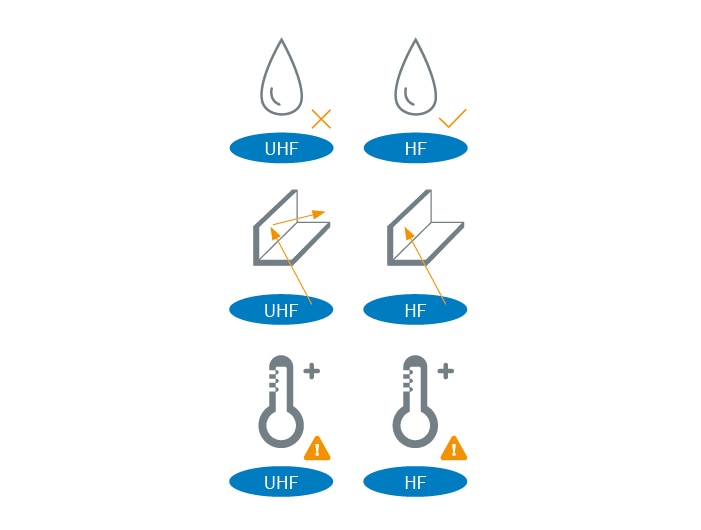

The immediate environment can affect the RFID system.

Liquids between the RFID reader and RFID transponder as well as directly behind the transponder will have a negative impact, in particular with UHF RFID. The electromagnetic waves are absorbed, which prevents a reliable read.

In the case of the lower frequency technologies (LF RFID, HF RFID), liquids have little or hardly any effect.

Another source of interference apart from liquids is metal. Metal reflects (UHF RFID) or absorbs (HF RFID) radio waves and should therefore not be placed between the RFID reader and RFID transponder. RFID transponders can be applied directly to metal, however in this case special on-metal tags must be used or a clear space provided between the metal and RFID transponder.

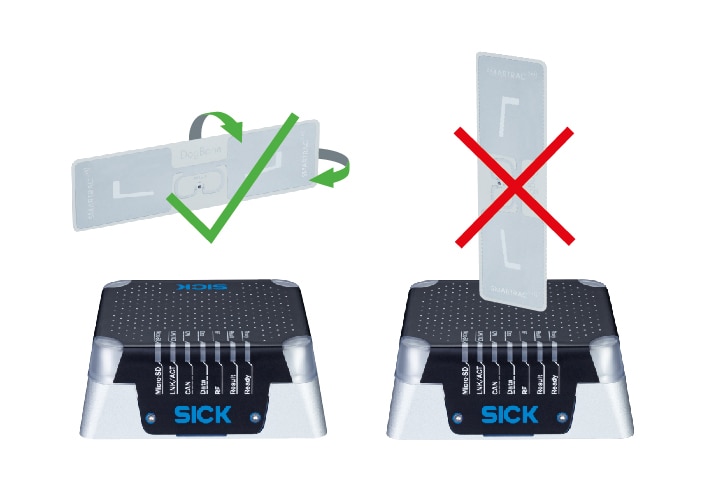

For these RFID transponders, particular care must be taken to correctly align them with the RFID reader.

For HF RFID, the antenna coil of the tag must be aligned so as to be parallel to the antenna coil of the reader.

For UHF RFID, there is significantly more flexibility regarding the alignment of the reader and transponder. A fundamental requirement is that the antennas of the reader and transponder must not be arranged orthogonal to one another.

-

What are RFID stickers, labels, hard tags, etc.?

The number of types of RFID transponders is growing as the acceptance and success of RFID technology increases in the market. Different tags solve a wide variety of tasks. There are a few terms that get used a lot. Here is an overview of the different design variants of RFID transponders.

Transponder type

Example

Features

Special features

Price

Stickers / labels

Antenna and chip with cover foil made from paper/plastic

Economical transponder format. Often used for container identification

$

Hard tags

Very rugged thanks to the plastic housing

Very rugged transponder. Often on-metal. Ideal for harsh ambient conditions, e.g., skid ID

$$$

Disc tags

Round transponder with mounting hole in the center

Frequently used in the LF/HF range

$$

Coin tags

Round transponder without a mounting hole

Frequently used in the LF/HF range

$$

ISO cards

Transponder in the format of a business card

Standardized format that is often used to control the access of people

$

Glass tags

Transponder made of glass

Standardized format that is often used for animal identification

$$

Cylinder tags

Transponder in a cylindrical shape

The RFID reader under the vehicle reads tags on the floor/ground to determine the position of the vehicle

$$

-

How much data can an RFID tag/transponder hold?

The usable data capacity depends on the memory size of the chipintegrated into the RFID tag. There are a wide variety of chips for transponders, and they differ not only in regard to the available memory size but also their sensitivity.

Generally speaking, the more memory capacity a transponder has the higher its price will be.

The following therefore apply when selecting a suitable transponder:

As much memory capacity as necessary, as little as possible. Lower data quantities also reduce the read and write times in the process.

For simple applications in the UHF range, chips with 96 bits of data memory are normally used.

So-called high-memory tags use chips that can store up to 64,000 bits of data.

-

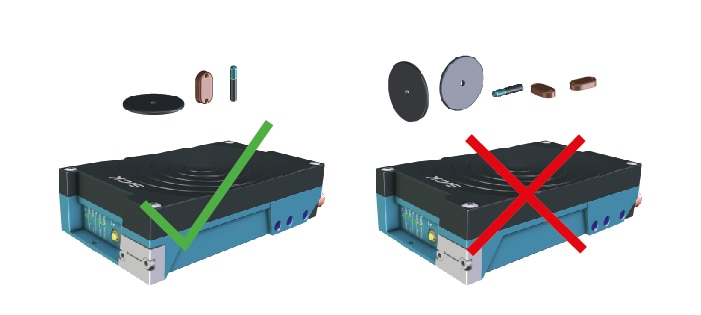

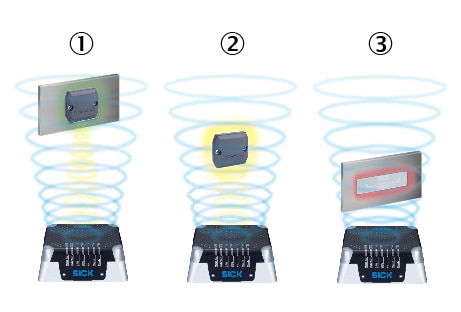

What is the purpose of on-metal tags and why are they so expensive?

Mounting a standard RFID transponder on a metallic surface drastically reduces its sensitivity and it may no longer be able to be reliably read or written to. The metallic background detunes the resonance frequency of standard transponders.

So-called “on-metal tags” are RFID transponders that have been specifically developed for mounting on metal.

On-metal tags can also be reliably identified on metal thanks to the integration of a spacer between the metal and tag, or special materials on the rear that shield the properties pf the metal. The price of on-metal tags starts at just a few euros.

Note: The sensing range of on-metal tags decreases enormously if they are mounted on non-metallic materials.

RFID transponder on metal

RFID transponder on metal- 1) On-metal transponder on metal

- 2) On-metal transponder not on metal

- 3) Non-metallic transponder on metal

-

What must be considered when selecting a transponder?

The product selection for an RFID system often begins with the RFID transponder. This will identify several possible options.

The required sensing range can often help narrow down the most suitable transponders. This will also determine the appropriate RFID technology to use (HF RFID or UHF RFID).

It is also necessary to establish whether the transponders will be used on metallic materials, in high temperature processes (> 150 °C) or in ATEX zones and/or come into contact with liquids.

The memory capacity can often also play a decisive role. In this case it is necessary to determine whether all of the data can be stored on the transponder (“data on tag”), or whether a serial number as a reference for a database in the system will suffice (“data on system”).

For UHF transponders, the geographical region of the transponder also needs to be taken into consideration. ETSI and FCC transponders are optimized for specific frequencies and therefore for particular regions/countries.

Global transponders are suitable for worldwide use but do not achieve the same performance as the specialized transponders.

- ETSI transponder (865 MHz to 868 MHz)

- FCC transponder (902 MHz to 928 MHz)

- Global transponder (865 MHz to 928 MHz)

The prerequisite for communication between the RFID reader and RFID transponder is the compatibility of both components.

- UHF reader ↔ UHF transponder; in accordance with ISO/IEC18000-6C / EPC Class 1 Gen 2

- HF reader ↔ HF transponder; in accordance with ISO/IEC 15693

For assistance with selecting the right transponder, see the product selection guide on our website.

-

What is the difference between RFID and NFC?

Near-field communication (NFC) is based on RFID protocols and uses the same frequency as HF RFID systems (13.56 MHz).

An NFC system has a sensing range of only a few centimeters, i.e. very short. NFC systems are therefore suitable for secure applications, for example access control or contactless payment.

The key difference to RFID is that an NFC device can act not only as a reader but also as a tag (card emulation mode).

SICK does not offer any NFC systems.

-

Is RFID a sensor?

RFID readers are not sensors in the traditional sense because they do not make any physical or chemical measurements.

RFID readers, together with fixed mount bar code scanners, mobile hand-held scanners and camera-based code readers, constitute identification technologies (auto-ID).

-

Is the radiation emitted by the RFID antenna harmful?

RFID uses similar frequencies and power ratings as mobile communications. In Europe, for example, they must not exceed a max. output power of 2 W.

RFID readers are subject to applicable standards and are classified as no more dangerous than cell phones in use.

-

Can tags in a metal box be read using RFID technology?

The radio waves of RFID readers do not penetrate metal. As long as one side of the box is open, the RFID reader can read the tag in the metal box. Tags inside a completely closed metal box cannot be identified using RFID.

-

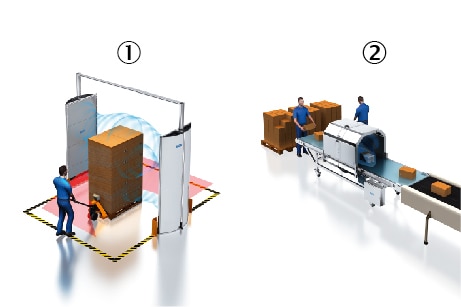

How many tags can be read simultaneously?

It is often a requirement in logistic processes to be able to read many transponders simultaneously. This is also referred to as bulk reading.

UHF RFID technology, in particular, has been developed to read several hundred tags per second. The maximum number depends primarily on the quantity of data to be transmitted and the configured data transmission rate/modulation. It should be noted here that a higher data transmission rate generally results in a lower sensitivity – more distant tags are read less well.

RFID system solutions from SICK

RFID system solutions from SICK- 1) RFGS Pro RFID gate

- 2) RFMS Pro RFID tunnel

Due to the smaller reading field, HF RFID can only identify a few tags simultaneously.

-

Can positions be recorded with RFID?

RFID is primarily an identification technology. As soon as an RFID transponder enters the reading field of a static RFID reader, the position of the object can be determined unambiguously. The accuracy of the position detection depends on the size of the reading field of the RFID reader. If the transponder is located outside the reading field, no position information can be determined.

-

Can I navigate using RFID?

RFID chips deliver no precise information about the location, alignment, and direction of movement of objects. RFID can support other navigation technologies (GPS, LiDAR etc.), e.g, when the RFID transponder enters the reading field of an RFID reader after arriving in a particular zone/area.

-

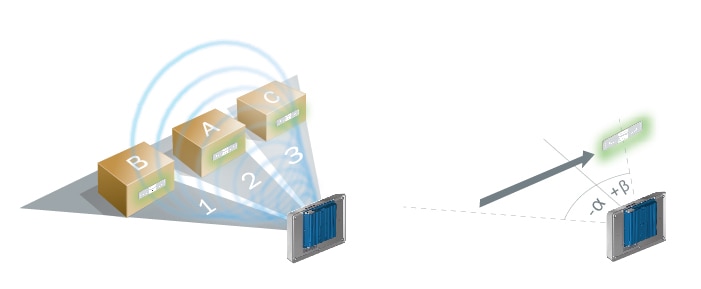

Can RFID readers measure angles?

Standard RFID readers cannot determine the angle between the RFID reader and the RFID transponder.

Special UHF RFID readers, however, are able to determine the angle between the RFID reader and the RFID transponder.

A distinction is made between:

- Zone detection: The reader checks whether the transponder is located within a specific angular range in front of the reader and whether it is entering or exiting that range. In the example illustration, the reader detects the object B in zone 1

- Direction detection: The reader determines the direction of movement of the transponder. In the example illustration, the reader detects that the transponder is moving from left to right.

Typical RFID applications

-

Industrial vehicles

-

Airport

-

Traffic

-

Building management

-

Automotive and parts suppliers

-

Tires

-

Electronics

-

Battery

-

Handling and assembly

-

Food and beverage

-

Wood

-

Mining

-

Waste and recycling