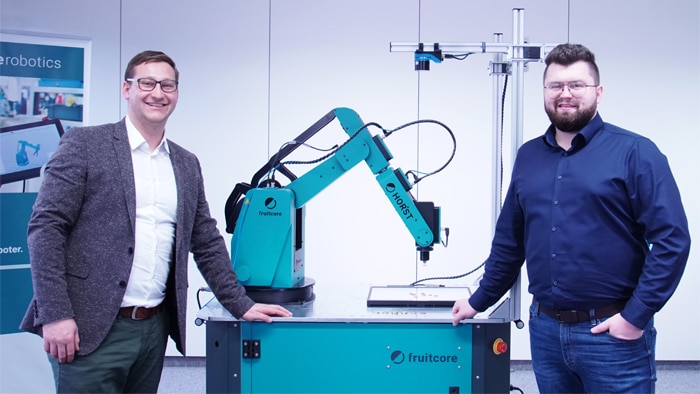

In the future, automation with industrial robots will also be getting more interesting for smaller companies. Because fruitcore robotics, based in the German city of Constance, has developed the HORST industrial robot for flexible and easy-to-implement automation solutions. The safety and vision solutions from SICK help fulfill safety requirements and perform a variety of new tasks.

Here comes HORST: An easy-to-use industrial robot from fruitcore robotics

The magic word “automation” takes precedence for every industrial company that needs to increase quantities and make work processes more efficient. We want to help companies of all sizes automate easily and efficiently,” explains Eduard Reiswich, Head of Robot Systems at fruitcore robotics. The young company aims to make automation with industrial robots possible for the masses. The robot systems, from the hardware to the software, are Made in Germany.

One arm, six axes, thousands of possibilities

HORST combines the advantages of conventional industrial robots with those of cobots. The result: A fast and efficient system in different load capacity and range classes. The description “Highly Optimized Robotic Systems Technology” was shortened to the acronym HORST. The down-to-earth name conveys how uncomplicated such a system can be, especially for smaller industrial companies. This is apparent in the programming of the robot: The intuitive graphical user interface does not require any special knowledge. “When it comes to how to control the industrial robot, we had a clear goal in mind: It should be as simple as a smartphone so that anyone can figure it out right away,” says Reiswich.

Pick-and-place with the right robotic guidance system: HORST can do it

Loading, unloading, stacking, sorting, packing. The robot from fruitcore robotics can be combined with the PLOC2D robot guidance system from SICK for a wide range of pick-and-place applications. “This means we can identify the positions and orientations of components in a plane,” explains Reiswich.

The PLOC2D robot guidance system transmits position data and rotational positions of components to the robot controller. Using the recorded information, the robot is able to grip the properly aligned parts and precisely feed them to the next process.

A key advantage of the PLOC2D is the simple commissioning, meaning no vision expertise or programming knowledge required. The PLOC2D is configured using an intuitive user interface through a web browser.

Safe automation with HORST – thanks to monitoring with safety laser scanners

fruitcore robotics offers a mobile base station for the robot system as an optional accessory. Depending on the application, two safety laser scanners from the microScan3 series are attached here, enabling 360° monitoring. The safety laser scanners secure those hazardous areas of the robot station, which are freely accessible for the operator. Any approaching person is reliably detected. Entering the respective area automatically triggers the safe state of the robot, while optimal accessibility remains in place for the system operator.

“Conventional laser scanners are not known for this type of HDDM scanning technology,” explains Jonathan Ruf, Regional Account Manager at SICK. “It makes the mobile station very rugged, and thus reliable.” The standardized interfaces and internal configuration memory facilitate integration of the microScan3 into the robot system, saving time and money.

Beyond the sensor technology: SICK is a partner in digitalization with that something extra

Eduard Reiswich was also impressed by the reliable communication with SICK and its extraordinary understanding of the issues. “With workshops and loan equipment as well as via short service routes, we were able to gain knowledge and quickly answer many questions about safety technology.” For Jonathan Ruf, the early exchange between the companies was also important: “We were able to contribute to the growth of the company early on. However, cooperation as equals has always been the key to success.” Eduard Reiswich has a similar view: “Collaboration with SICK is of considerable value to us.”

He would like companies in the region to stick together, especially when it comes to the pandemic. When thinking about the international challenges of tomorrow, the motto for fruitcore robotics and SICK is the same: “Together from the region - together for the region.”

Read more

Productive and safe interaction between humans and KUKA robots

Faster in depalletizing: Robots see more with 3D snapshot technology

The new mobility: How sensors control the cobots of the future

Vision technology for Cobots

Working together as equals

Thanks to sensors from SICK, robots perceive more precisely. For all challenges in the field of robotics: Robot Vision, Safe Robotics, End-of-Arm Tooling, and Position Feedback.

Learn more