Safe, fast and cost-efficient – that’s the GESSbot Gb350 automated guided vehicle (AGV) from W. Gessmann GmbH in Leingarten in southern Germany. When developing this automation solution for internal material flows, the company turned to sensor solutions and safety services from SICK.

Autonomy and flexibility in intralogistics – the road is clear for automated guided vehicles

Sensors are the eyes and ears of automated guided vehicles

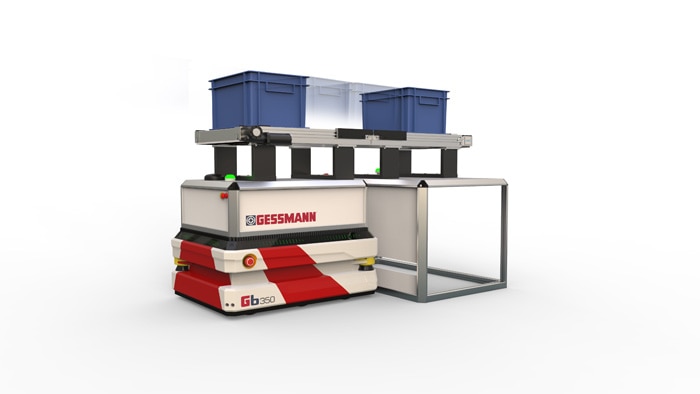

Close collaboration between W. Gessmann GmbH and SICK has resulted in an efficient solution for smooth internal material flows – the GESSbot Gb350. The sensor-supported automated guided vehicle carries loads of up to 350 kilograms and handles inclines of up to five percent. Its battery life lasts up to twelve hours. Thanks to state-of-the-art sensor technology from SICK, the Gb350 can find its way almost everywhere. LiDAR sensors map the surroundings, detect obstacles, and register changes. This prevents collisions with barriers, a decisive advantage for vehicles and products of this type. Ultrasonic sensors make sure even glass fronts are visible. If a person is in the surroundings, an S300 safety laser scanner installed in the Gb350 detects this and reports it to the Flexi Soft safety controller. This ensures that the transport system stops before it gets dangerous.

To ensure smooth internal material flows, the AGV transports goods between transfer stations and loading stations. The optional elevator control even allows the Gb350 to use elevators. The modular setup of the GESSbot Gb350 means it can be adapted to different requirements; this makes it a flexible, fully adaptable industrial application. A milling machine can be individually loaded and unloaded in combination with the Gb350 automated guided vehicle, meaning different parts can be processed.

The new player on the team

The features and options of the Gb350 make the automated guided vehicle a reliable assistant in production and logistics. This system is very adaptable to individualized requirements, for instance if a rack structure or roller conveyors with automatic loading and unloading function or scissor lift system are needed. This performance coupled with sophisticated sensor technology from SICK not only ensures that the AGV system relieves employees of taxing physical work; it can also be used for ghost shifts outside of regular working hours. This is a factor of increasing significance in view of demographic changes, which in many companies mean a shortage of skilled workers and a higher average employee age.

Likable multi-talent

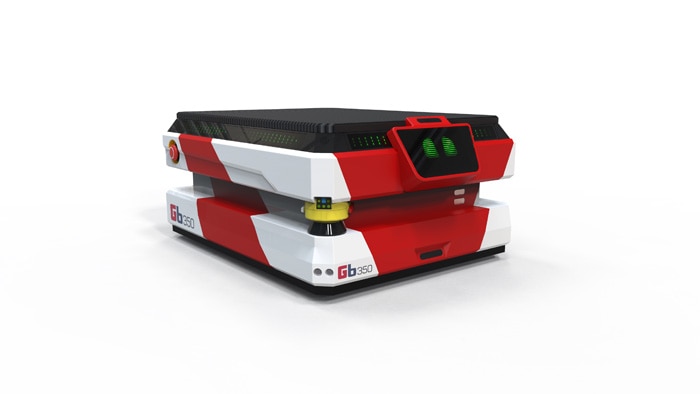

During planning and construction, the designers and engineers managed to give the AGV an almost human appearance: Two lights in the front area look like a pair of bright green eyes that winks at colleagues as they pass by. The appealing design and excellent support with daily work duties mean that the automated guided vehicles quickly become welcome members of the team. “When it comes to automating processes, every application first needs to be accepted,” explains Martin Eggensperger, who heads development at W. Gessmann GmbH. “The GESSbot appeals to people on an emotional level; some people even want to take a selfie with it at trade shows. This also helps when it is introduced in practical operations.”

It’s what’s inside that counts

Inside the automated guided vehicle, sensors from SICK perform essential functions. Measurement data from the safety laser scanner orients it in space. The speed and steering angle of the vehicle are also detected with the help of the MOC module and the DFS60S safety encoder. The Flexi Soft safety controller evaluates this data to reliably detect obstacles and act appropriately in the event of danger. Flexi Line offers the level of flexibility that modern safety concepts require. For instance, the Flexi Soft of the basic vehicle is simply and reliably networked with the safety controller of the modular structure with the integrated Flexi Line interface. This means that the GESSbot Gb350 scores points not only in terms of safety, but there are also virtually no limits to its modularity.

Achieving success together

The Gb350 is the result of the partnership between W. Gessmann GmbH and SICK, which from the very beginning was marked by great faith in each other’s technological expertise and market knowledge. “Together we have created a product that we will continue to develop and adapt to customer requirements,” explains project manager Steffen Kuhnle from W. Gessmann GmbH. This means the GESSbot Gb350 automated guided vehicle is ideally positioned for a wide range of tasks and internal transports at medium-sized German companies. In addition to SICK products, W. Gessmann GmbH relies on the approach to service and systems at SICK. This aim of this approach is providing hardware, software, and service for mobile platforms from a single source, thus meeting the customer’s needs for flexibility and variability.

Read more

Autonomous vehicles from Asseco CEIT – fully equipped with intelligent sensor technology

Take a load off: optimize loading and displacement by autonomous mobile robots

Everything in flux: mobile robots in retail, hygiene or logistics

SICK and SOTO: A new mobile robot for industrial production

Мобильные роботы:

переход в новые измерения

Робототехника не стоит на месте: в производстве, логистике или сфере услуг. Сенсорные решения для всех вариантов мобильных роботов