-

Home

-

-

Revolution in digital motor feedback communication: ten years of HIPERFACE DSL one cable technology

-

Home

-

Revolution in digital motor feedback communication: ten years of HIPERFACE DSL one cable technology

Revolution in digital motor feedback communication: ten years of HIPERFACE DSL one cable technology

Nov 25, 2024

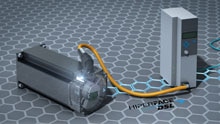

“Less costs and space requirements, a high level of investment certainty – as well as machine safety – in the electric drive technology area, HIPERFACE DSL is opening up a wide variety of advantages for motor producers and machine builders when developing and integrating servo drive systems.” This is the promise SICK made more than ten years ago when it introduced on the market the first interface in one cable technology for communication between servo motors and servo controllers.

How has this pioneer in digital motor feedback communication and its technology established itself and developed in the meantime, what innovations does HIPERFACE DSL as the original one cable technology offer currently and in the future? An interview with two experts.

The SICK experts Clemens Bitsch, Strategic Product Manager & Business Development Manager, and Michael Pfister, Head of Product Management Motor Feedback Systems know the answers to these and other questions.

What is HIPERFACE DSL about?

Clemens Bitsch: HIPERFACE DSL – the DSL stands for Digital Servo Link – was the world’s first interface between servo motors and servo controllers in one cable technology when it was launched on the market in 2011. The triggers for this development were firstly Industry 4.0 and the impending digitalization in many areas of machine and drive technology. Secondly, there was a requirement for a cost-saving communication channel in the form of a standardized interface. HIPERFACE DSL was created on the basis of the experiences gained with the hybrid interface HIPERFACE, which had already been developed by the company Stegmann, later SICK Stegmann. The aim of the new one cable technology was to enable a reliable and interference-free data transmission between the drive controller and motor over two wires integrated directly into an up to 100 m long motor cable. Device technology-wise, this digital interface halved the costs for connectors, cables and cabling work. It also eliminated the need for expensive analog components or a separate controller input for external sensor data on the controller side. Furthermore, motor, controller and systems manufacturers profit from the optimization of the control circuit as a result of an automatic synchronization of the control cycle. Finally, HIPERFACE DSL not only supports the functionality of an electronic type plate for automatic controller parameterization, but the safety technology incorporated into the digital data communication also makes it suitable for applications up to SIL3 according to IEC 61508 and performance level e according to EN ISO 13849-1.

What characterizes the success story of HIPERFACE DSL?

Michael Pfister: HIPERFACE DSL really caught on in the market with drive and control technology companies when the first applications were solved in 2012. At the same time, the study of a renowned information and consulting company also confirmed one cable technology as a current megatrend at the time – as it still does now – for example the fact that the number of drive manufacturers who have adopted HIPERFACE DSL for their motor feedback solutions is already significantly large and continuing to grow. Industry experts also predicted that this purely digital motor feedback protocol was the way of the future ‘because the new HIPERFACE DSL interface saves costs and space while at the same time offering a high level of investment certainty and machine safety.’ The supplier market therefore jumped on the HIPERFACE DSL bandwagon early as well. Well-known cable manufacturers, for example, presented suitable cables for this digital interface standard in response to the rapid spread of the one cable technology from SICK. These were soon followed by the manufacturers of microprocessors who integrated the digital protocol into their products. Consequently, there now exists an established infrastructure of companies associated with HIPERFACE DSL who are offering tried-and-proven components for this digital interface. This “hassle-free package” of offerings for HIPERFACE DSL creates the prerequisites for process stability with the associated required material throughput in harsh everyday production environments.

Clemens Bitsch: Further indications of the success of HIPERFACE DSL are the more than 60 motor and controller manufacturers that actively support this standard, and the strong demand for the technology in the market. Firstly, this has resulted in us also licensing HIPERFACE DSL to third-party manufacturers since 2017. Secondly, we regard as a sign of success of HIPERFACE DSL that there are now also imitators of the original in the market for digital motor-controller communication. The market trend – including in regard to the current rate of growth in HIPERFACE DSL-suitable motor feedback systems from SICK – continues to be positive to this day.

What are the current trends relating to HIPERFACE DSL?

Michael Pfister: While HIPERFACE DSL in the beginning and in recent years has mainly still been associated with one cable technology, the topic of data utilization and vertical integration is now also coming into play. Besides data transmission, another key issue is data availability in the IT system. Our solutions make it possible to provide both raw data and also pre-processed data packages. Furthermore, SICK Services enables us to implement the visualization of data, for example on and via the cloud. The issue of safety is also becoming more important. Our customers want their drive technology to be safe to ensure the people working in production logistics are protected according to the latest normative standards.

What are the latest HIPERFACE DSL® innovations at SICK?

Clemens Bitsch: SICK has been very active in this area in recent years and now has a HIPERFACE DSL portfolio for servo, torque and linear drives. Our latest innovation expands the compact motor feedback systems in the EDS/EDM35 product family. We have succeeded in miniaturizing the sHub sensor module to the point where it fits into the space-saving housing of the sensor itself. This now makes it possible to integrate into a servo motor with a 40 mm edge dimension a sensor that provides not only safe absolute position data for control purposes but also additional vibration and air humidity data for condition monitoring. These turn the motor feedback system into a smart early warning system should bearing damage or leaks arise.

What does the future hold for HDSL?

Michael Pfister: Motor and controller manufacturers will continue to rely on HIPERFACE DSL as a future-proof technology in the market of suppliers of one cable solutions. Our discussions with our customers and with HIPERFACE DSL component manufacturers, the sales trends, and the achieved market penetration confirm this. We are constantly receiving ideas and improvement suggestions via customer feedback, which flow into both product-related further and new developments as well as extensions of the interface itself. Furthermore, we are continuing to work on digital services that open up new possibilities for using our smart motor feedback systems in conjunction with servo controllers.

Motor feedback systems

Safe absolute position with HIPERFACE DSL® for demanding servo applications

EDS/EDM35

Safe speed measurement with HIPERFACE DSL® for standard servo applications

EKS/EKM36

Safe absolute position with HIPERFACE DSL® for rugged servo applications

EES/EEM37

Is the one cable connection HIPERFACE DSL® for electric motors soon to be the automation standard?

Lesen Sie mehr

Realize the highest machine availability with Smart Motor Sensors

Read more

Please wait a moment...

Your request is being processed and may take a few seconds.