It is no longer enough to automate single processes and individual production steps. Modern production and logistics facilities need the efficiency that comes from holistic solutions – and take the entire facility into account. And holistic solutions require more cooperative projects like those between HIKROBOT and SICK. As global manufacturer, HIKROBOT has a wide range of products that covers multiple types of robots and self-developed software platforms. You will find their robots working in industries ranging from food to consumer electronics, automotive, and pharmaceuticals. Thanks to SICK’s safety laser scanner nanoScan3, these robots are able to navigate all types of these environments while simultaneously ensuring a safe operation and protecting workers.

Safety laser scanner technology enables mobile robots to navigate work environment safely

Robots navigate work environment safely with high-precision mapping software

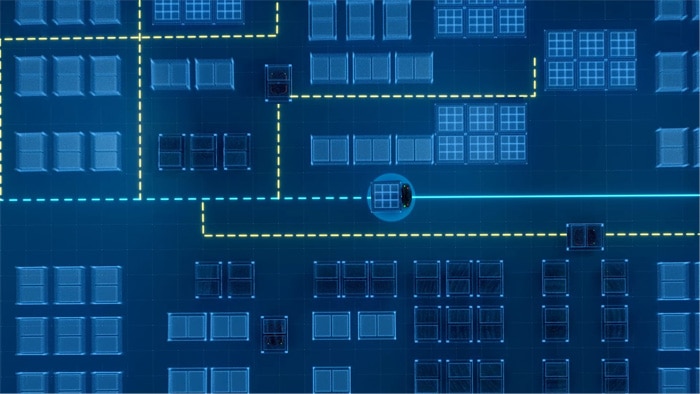

When it comes to adapting to a new environment, the basic concept is simple. Like any new employee, the robot first has to become familiar with the area it works in. Using the SLAM (Simultaneous Localization and Mapping) method, the robot drives through the work area and uploads the information provided by the SICK safety laser scanner nanoScan3 to a mapping software. Once the map has been finalized, it is downloaded to the robot’s control board and used by the robot to establish the virtual roads that will guide it through the work area. To ensure optimal operation, the robot carries out tests to ensure that the area is properly mapped and that it can run smoothly.

High-precision measurement data ensures uninterrupted operation and lower implementation costs

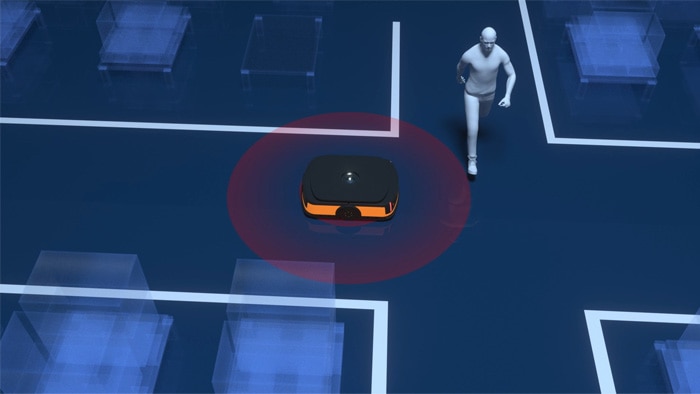

The nanoScan3 functions as the eyes of the robot, guiding it to its various destinations. Thanks to the safeHDDM® scan technology, it is extremely resistant to ambient light, dust, or dirt and consistently delivers reliable, high-precision measurement data. That means that in the course of a busy industrial workday, when the robot faces fine particles from production or harsh, high-frequency lighting, the robot will continue to operate smoothly. That is a great boost to productivity – and it can also reduce implementation costs by reducing the need to invest in very clean or dust-free working environments.

The nanoScan3’s environmental perception capabilities enable the robot to deal with complicated surroundings. In addition, real-time scanning protects both the robot and the environment it is in. The robot is immediately able to recognize and then deal with unexpected situations such as dropped goods on the shop floor or people crossing through the aisles.

Cooperation on advanced safety technology paves the way ahead

The cooperation between HIKROBOT and SICK is a complete success story. The small dimensions of the nanoScan3 make it easy to integrate the device into compact robots. And the advanced technology of this safety laser scanner enables HIKROBOT to produce easy to use, cost-effective solutions. With the SICK tech team’s dedicated technical and after-sales services, a very trusting relationship has developed between the two companies, which bodes well for future endeavors.

To date, HIKROBOT has already provided robotic solutions and products to over 1000 customers all over the world. Its customers include such companies as DHL, FAW-Volkswagen, Superdry, and A Perry. Through the joint efforts with SICK, the company is looking to continue this success story and provide the market with even more value and possibilities.

Read more

Ultracompact mobile robots optimize the process chain

The perfect size of the protective field on an industrial autonomous vehicle

Light at the end of the tunnel - disinfection using UV light and nanoScan3