The metaverse: By this we mean a digital, three-dimensional, interactive space in which the physical and virtual world merge into one. As an “industrial metaverse”, it opens up for us new possibilities for product development and collaboration with our customers. A special think tank at SICK is working on this topic. In our SICKnificant podcast, Arnd Sörensen, Project Manager Virtualisation, explains what these possibilities are.

Industrial metaverse: what opportunities the new virtual world offers us

Arnd Sörensen describes the task of his team as follows: “In the Think Tank, we observe the digital world. We focus on disruptive technologies that have the potential to bring about a lot of change. We investigate whether and how SICK can utilize these. The metaverse – and for us at SICK, the industrial metaverse in particular – is such a technology.”

The industrial metaverse is an umbrella term that covers many different technologies. Examples include augmented reality, which combines the digital and analog world, or virtual reality, i.e. a completely virtual space. In the industrial area, these technologies already allow, for example, very large machines that cannot be easily transported to be demonstrated at trade fairs or to the customer using a three-dimensional, virtual model. “That opens up completely new possibilities for product development and collaboration with customers. Our think tank team has been tasked with creating a foundation within the company what would enable as many areas as possible to profit from this technology,” says Arnd Sörensen.

Virtual customer center: Solution development has never been this realistic

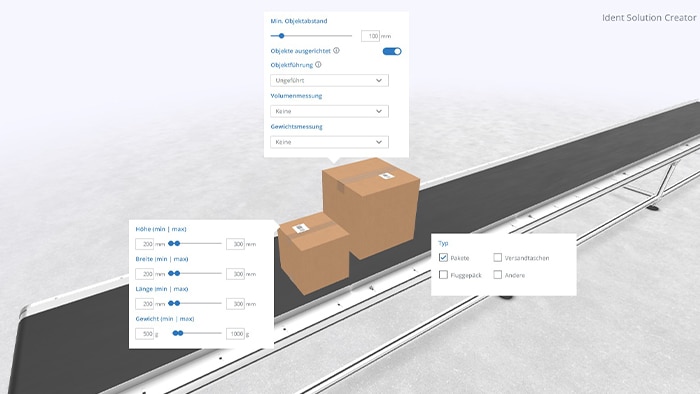

In general, SICK’s business involves not only “off the rack” products but increasingly also the development of custom solutions. This is exactly where the advantages of the industrial metaverse come into their own: “We can present applications or solve concrete problems, sometimes even better than we could in the real world,” says Arnd Sörensen.

A concrete example for the use of the metaverse for SICK might be a virtual customer center where we can meet with customers or potential prospects: “We present our products and solutions there, or simulate a custom solution tailored to the particular customer – for example a logistics application where objects are moving on a conveyor belt. We can show, for example, where our sensors are placed, what dimensions they have, and how many of them are required for this specific application. This enables our customers to get an impression of what the solution to their problem looks like.”

SICK took its first step in the industrial metaverse direction back in 2022 when in launched the SARA App – short for “SICK Augmented Reality Assistant”: It facilitates troubleshooting, servicing and commissioning via augmented reality by linking sensor data to the real world.

The next step: Using a digital twin

In future it will also be possible, for example, to meet customers in a virtual space to jointly observe there the “digital twin” of a real life system and, if necessary, to rectify a problem. This type of virtual representation can have various levels of detail: from a simple three-dimensional model right through to a digital simulation of real functions, mechanics, and the electronics. “Using a digital twin in the industrial metaverse, when a problem exists we can see exactly whether certain changes or modifications work in reality”, says the virtualization specialist Sörensen. “The technology for such applications – both hardware and software – already exists and is currently developing rapidly. We too are working on such an application for SICK.”

The nature of collaboration will fundamentally change

With all the advantages that the industrial metaverse offers, the obligatory question arises: Will everything in future only take place in a virtual space and no longer in the real world? Not really, says Arnd Sörensen: “It is important to identify when it is actually advantageous for us to use the industrial metaverse. There are many cases where it opens up fascinating new possibilities. But there are also scenarios where it is definitely better to meet in reality. I am therefore certain that not everything will take place in the metaverse in future.”

Hybrid solutions are also conceivable. For example in our logistics technology center in Reute, where real applications are on display. “Someone from Australia might not want to go to the trouble of traveling there, however. For him or her, a reproduction in the industrial metaverse would no doubt be the better solution,” says Arnd Sörensen.

The resume of a virtualization specialist reflects the fascination that this technology holds: “There's heaps of stuff going on here, and I am certain that there will be a lot of excellent ideas for how to exploit these new possibilities. One thing is certain: We are only at the beginning of a development that will fundamentally change the way we work and collaborate,” says Sörensen.