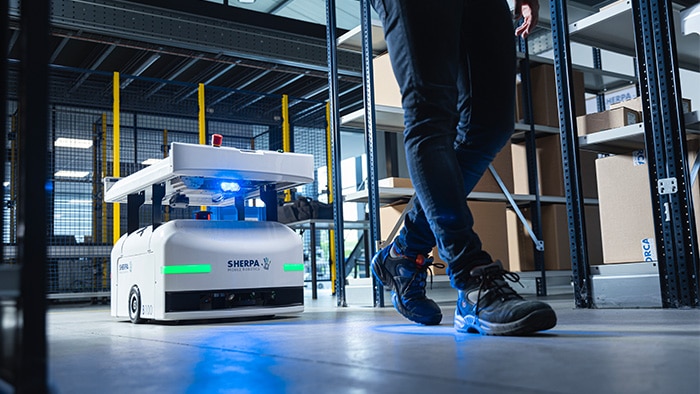

Integrating mobile robots that work safely in the immediate vicinity of operators and machines – that is the aim of SHERPA MOBILE ROBOTICS (SMR). The autonomous and mobile robots allow diverse solutions: for example making work operations easier or automating the transfer of a load from A to B, thereby boosting mobility and productivity.

Mobile robots from SHERPA MOBILE ROBOTICS boost mobility and productivity

High safety requirements for users

SHERPA MOBILE ROBOTICS offers its customers a whole range of solutions. Their first two customizable autonomous mobile robots (AMR) provide customers with solutions for absolutely every scenario. The first AMR transports pallets and has a load bearing capacity of up to one tonne, the second transports containers.

Safety was the top priority for the developers. To ensure the highest level of safety for the robot in its environment, SHERPA MOBILE ROBOTICS approached SICK. Laurent Troesch, R&D at SMR, explains the background of the collaboration: “Initially we envisaged an architecture for the safety functions that used non-certified components (sensors, controllers, etc.) even through we were aiming for Performance Level d for most of them. We quickly noticed that such an approach would be very complex and time-consuming, which would not allow the speedy market launch of a reliable series of robots.

Furthermore, tailored solutions such as this are rather inflexible and are not particularly suitable for upgrading or use in future robot series. In developing our robots, we were looking instead for efficient and flexible solutions that can be quickly integrated. The exchange of ideas and support from SICK helped us a lot with this.”

Stéphane Rauline, Technical Sales Engineer at SICK France took on the challenge from SMR and got the collaboration between the two teams going. The engineers at SMR were looking for safety laser scanners and safety encoders. They therefore decided to go with the S300 safety laser scanner and the DFS60S safety encoder. For the SHERPA-P, they are using the nanoScan3 safety laser scanner and the Flexi Soft Drive Monitor safety controller. This enables the SHERPA products to move about with absolute safety even in sometimes confined surroundings.

Competent and flexible support

Jeffrey Yannou, mobile applications expert at SICK France, was responsible for supporting SHERPA throughout the entire project. Thanks to this collaboration, a quick market launch was achieved. Renowned companies such as Siemens, Airbus, Fnac, Darty, and FPT Industrial are already using SHERPA robots. FPT (Fiat Powertrain Technologies) Industrial in Bourbon-Lancy in the department of Saône-et-Loire is even using a whole fleet of mobile robots from SHERPA. The mobile robots are making assembly tasks easier and reducing the risk when transporting loads. Their smooth operation is also boosting productivity.

Another advantage of SHERPA robots is that they can move safely between operators, manned forklift trucks, and AGVs. “Thanks to the integration of six robots we have gained concrete experience in fleet management in a real-life environment. We will be able to apply this new knowledge for customers who are already waiting for this type of technology,” explains Damien Winling, Technical Director at SMR.

This is only the beginning of a big adventure for SHERPA and its mobile robots. They are putting their trust in the latest technologies from SICK that make the mobile robots even more efficient and safe. A shared journey for both companies that has only just begun.

Read more

Safety laser scanner technology enables mobile robots to navigate work environment safely

Ultracompact mobile robots optimize the process chain

Autonomy and flexibility in intralogistics – the road is clear for automated guided vehicles

Mobile robots:

Move into new dimensions

Robotics is on the move, whether it be in production, logistics or service. Sensor solutions for all variants of mobile robots