It’s wobbling concerningly, but this stacking on top of one another is unavoidable due to lack of space. The automatic stacking of goods in a bulk storage area continues to pose technical challenges. It becomes all the more difficult when it involves goods that are not rigid. Anyone who has ever stacked several six packs of PET bottles knows how challenging this can be. And it doesn’t get any easy at a larger scale, of course. That’s why ek robotics in collaboration with SICK employed 3D cameras in conjunction with an innovative image analysis software to tackle this task and successfully tested it at a customer in a pilot project.

Stacked stability: 3D snapshot camera ensures balance

The ability of automated guided vehicles to automatically store and retrieve pallets is still very often limited when the load on the pallets is unstable and can slip during transport. An accurate process is absolutely essential, especially when pallets need to be stacked. This process can now be implemented using high-performance, industrial grade 3D cameras whose task it is to record three-dimensional data on the size, position and state of the load as well as important information about the properties of its surroundings.

3D snapshot technology as the key to success

The Visionary-T 3D vision sensor that was used works on the principle of optical time-of-flight measurement. The 3D camera sends light signals out into the surrounding area and receives the reflected signals again. When mounted underneath the fork arms of the autonomous transport robot (ATR), the Visionary-T thereby captures a three-dimensional representation of the entire area in front of the fork arms.

How the autonomous forklift truck learns to see

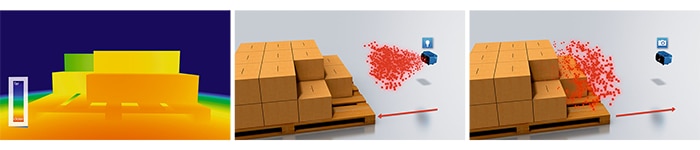

For each pixel location, the Visionary-T receives by means of the 3D time-of-flight technology the reflected light and calculates with the help of the phase shift the distance between the camera and the objects in the scene. Different phase shifts of the light correspond to different distances. In this way, several ten thousands of pixels are recorded simultaneously with no moving physical parts inside the camera. This allows 3D point clouds to be recorded in real time even for static scenes. Because the distance information is recorded “in a single shot”, this is also referred to as 3D snapshot technology – the forklift can “see”.

The requisite ruggedness for industrial applications is evident not only in the housing used, but also in the fact that the camera can be operated 24/7 and delivers precise and reliable 3D data even in difficult light conditions and fluctuating temperatures. This is ensured for the SICK camera by, amongst other things, a powerful illumination unit, a sophisticated thermal management system as well as intelligent pre-processing of the captured 3D raw data.

Safe pickup and stacking of unstable goods

A pioneering solution for automated loading and unloading by an intelligent automated guided system using the Visionary-T was developed in close collaboration with the AGV system manufacturer ek robotics in Rosengarten near Hamburg. The data recorded by the camera are evaluated in real time with the help of software developed by ek robotics. Karsten Bohlmann, Head of Research & Development at ek robotics, describes it as follows: “We have taught the forklift to see. The vehicle is therefore able to detect the exact type and position of the goods being transported as well as the pallets. This has been refined to the point where the AGV can distinguish, for example, whether the identified upper edge of the load is the packing film or the load itself. This enables the transport robot to safely pick up and safely transport even unstable loads of unequal height.”

Total success even for empty bottles

The proof of the pudding is in the eating. While trialing the transport of empty PET bottles to test the reliability of the process, it became apparent that the solution results in a significantly lower error rate compared to manual control. Both stacking and unstacking were able to be performed with a higher level of precision and less transport damage while also achieve maximum operational safety. One wouldn’t want to understate the case after this success: Given the complexity of the task, this development can be regarded as very impressive and also pioneering. ek robotics therefore plans to implement, in collaboration with SICK and using the 3D camera technology, more applications that have to date been considered challenging.

Read more

Camera system reduces collision risk for manned forklift trucks

Precise detection of pallet pockets using a 3D snapshotcamera

Clear path of forging and transport manipulators with 3D vision