You need a measurement expert if you want to take safe and accurate measurements of the concentration of hydrocarbons during production processes. The flame ionization detector has proved to be a successful solution in analysis measurement technology. SICKs FID devices measure the total quantity of hydrocarbons when monitoring emissions or play a direct role in the process by acting as a gas warning device. SICK is currently the only manufacturer that meets the requirements set out in EN 50271 for measuring the lower explosive limit in air that contains solvents. This is a very important point as companies are required to adhere to legal requirements for explosion prevention and occupational safety at all times. And not forgetting environmental requirements, too.

Whenever hydrocarbons are released, stored, or transported, companies are required to comply with laws and regulations to remove the risk of accidents or damage to health as far as possible. Hydrocarbons form the main component of volatile organic compounds (Voc) in industrial emissions and are classed as harmful to the environment. When hydrocarbons evaporate and mix with the air, they may become explosive. This is precisely the reason why measurement technicians want to keep concentration levels firmly under control, even the lowest ranges where possible. And they want to stay safe. Measurement technology and analysis technology therefore play a crucial role in both process analytics and emission monitoring.

Impressive technology

Flame ionization detection is one of the most typical technologies used. It is ideal for applications where companies are required to provide quick and accurate readings of the total concentration of hydrocarbons during the gaseous phase. Compared to other technologies, this measurement approach records all hydrocarbons (no matter how complex the compound) with high levels of sensitivity and linearity.

Flame ionization detection is used in detectors (FID) for gas chromatography and for emission measurement. SICK is also on hand to help with the monitoring of volatile concentrations prior to exhaust air purification systems, the continuous monitoring of the lower explosive limit (LEL), and with leakage detection in vessels containing solvents. Better than many other FIDs: SICK's devices are in high demand.

Early warning

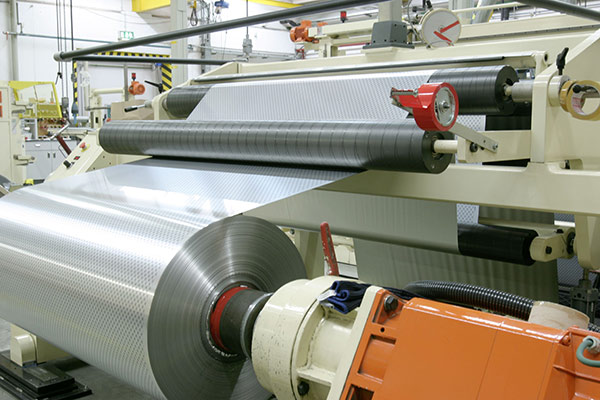

When large quantities of volatile and flammable hydrocarbons are released to mix with the air, there is always a risk of explosion if their concentration reaches a certain level. In some processes, it is impossible to prevent mixtures containing a high concentration of volatile hydrocarbons from dispersing in the air. As such, quick measurements for the lower explosive limit (LEL) and reliable information concerning the current status of the process air are important for plant safety. High concentrations of hydrocarbons may occur in coil coating facilities, for example. Strips of metal are coated with one or more layers, normally using materials like paints or plastics. These coatings are dissolved using solvents. Once coated, the coils are dried so that the solvent can evaporate. The finished product is a compound made up of a metallic base material and the coating. The product is processed further and used as a packaging material for consumer or blister packages, or used to manufacture household appliances (white goods). The coating process only takes a few minutes. Depending on the width of the coil, the metal coils move at a speed between 10 and 1,000 m/min. The coating and subsequent drying processes generate a waste gas that contains solvents. Companies that operate this type of plant are required to measure the %-LEL and keep the concentration of hydrocarbons below a certain level, e.g., below the 25% LEL. An FID device is very good at measuring these figures as it records the total quantity of all hydrocarbons. When an FID or similar device is used as a gas warning device for either switching off the system or simply for controlling it, the analyzer must comply with EN 50271:2011. This standard sets out a number of requirements and checks for electrical devices used for detecting and measuring combustible gases. The EuroFID3010 by SICK has been successfully certified according to this standard and is currently the only FID device on the market to have been so.

Going one step ahead: the EuroFID3010 total hydrocarbon gas analyzer

Companies have been using the EuroFID3010 extractive gas analyzer to successfully measure the LEL for several years now. Undergoing constant development, it has proved to be ideal for use in kilns or drying units and for processes in the chemical and HPI industry. The EuroFID3010 has very quick response times (T90) and monitors the value of the lower explosive limit for various solvent compounds. Rugged yet still exceptionally sensitive, the analyzer can also be used in waste gas purification systems. The LEL is measured as the air enters the system, with the corresponding emission values measured upon output.

A glimpse into the future of emission measurement

The GMS800 FIDOR extractive gas analyzer by SICK

A constant flow of information is crucial for emission monitoring. With availability of 99.5%, the compact GMS800 FIDOR total hydrocarbon gas analyzer is already a few steps ahead of its competitors. Available as a stand-alone variant or integrated into a measurement system, measurement technicians in waste incineration plants, power plants, and cement factories are very happy with both variants of the device. A rugged design, simple controls, quick circulation of gas, and accurate measurements provide a safe method for monitoring the total concentration of all hydrocarbons. The suitability test covered the analyzer, the measurement system and probe, heated sample gas inlet, and catalytic converter. As a result, the entire system is certified as suitable under EN 15267. Requirements concerning the availability and safe operation of analysis devices are expected to become even more stringent in future when it comes to functional safety. This not only poses a challenge to the facility operators but also to the manufacturers of analysis devices. SICK is there to help every step of the way.

- Product information: EuroFID total hydrocarbon gas analyzer, GMS800 FIDOR total hydrocarbon gas analyzer

- Product portfolio: extractive gas analyzers