The machine builder BalTec has developed a novel electrical riveting machine. The previously pneumatic drive has been replaced with servomotors, which make the connection technology much more efficient and fast. This machine from BalTec is setting a new benchmark in the industry. When searching for the best partner for safety devices during the exciting development process, SICK was the obvious choice.

Playing it safe: Swiss design engineers choose SICK safety solutions

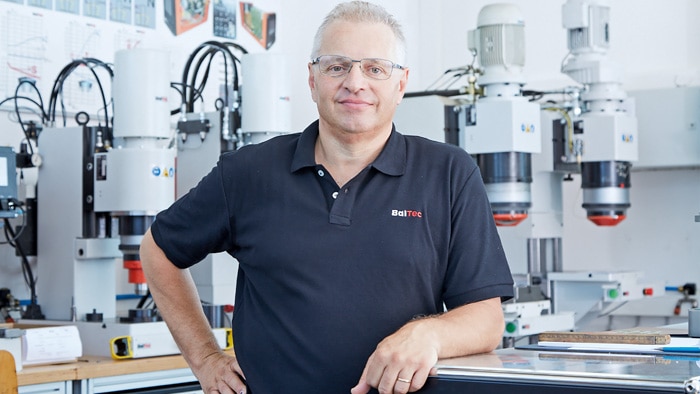

Klaus Huber is a mechanical engineer and individualist who likes to tread his own path but with a clear goal in mind: “In the end, it simply has to be ‘very good’! He started developing the electrically driven riveting machine in November 2015 as a product manager at the mid-sized BalTec Group. After four years of intensive work, the “Electric” product family with its two mechanical sizes reached market readiness for a total of four differ-ent force ranges. BalTec produces machines for connection technology and is the global leader in technologies for radial and wobble riveting as well as rolling and pressing. The 35 employees at the company’s head-quarters in the Swiss municipality of Pfäffikon, and a further 25 sales and service specialists on each of the continents make it their aim to help their customers, in particular in the automotive, furniture and electronics industries, achieve more productivity and efficiency. Domenico Mollo, Managing Director at BalTec, explains it like this: “We want to differentiate ourselves in the market and always find the best solution for the very specific requirements of each of our international clients. Equipping our machines with the best possible safety concept is absolutely essential to us.”

Driver of sustainability

Consequently, BalTec did not shy away from starting the costly and lengthy process of developing a servo controlled riveting machine. One goal was to be able to freely define the relative speeds of the die and rivet and therefore the forming process in all process steps, and to achieve more flexibility and faster cycle times. “As a rule, machines are strictly tied to one process technology with a relatively narrow processing window, but now the three classical forming processes – radial, orbital and roller – can be employed in one compact machine because the ser-vo technology allows us to freely select and specify all kinematic parameters, including the infeed rate and speed of rotation”, explains Huber in regards to the design advantages of the “Electric”. For users, this means they can replace up to three pneumatic machines with a single electrical one and quickly amortize the higher investment cost through greater efficiency, higher speeds, and perfect precision.

For BalTec, a strong driver for embarking on this multi-year development process was not only the issue of sustainability but also energy efficiency: “The ‘Electric’ has an efficiency of around 70 to 80 percent, whereas machines that use a compressor not only have high production and maintenance costs and an overall efficiency of less than 10 percent, but also suffer from noise and safety problems”, says Huber. The sophisticated niche players from Zurich Oberland weren’t satisfied, however, with just purchasing simple standard motors on the market. To achieve an optimal forming process and total process control with maximum compactness, Huber and his colleagues developed their own motors.

Exacting standards: everything from a single source

This constant striving for the best possible and most comprehensive solution is also reflected in the approach they took for the safety concept for the new machine. When in comes to machine safety, the Swiss mechan-ical engineers were not willing to make any compromises. One thing was clear to Klaus Huber from the start of the development process for the new riveting machine: “Only the most stringent safety standards would do.” The “Electric”, being a riveting machine, is not actually subject to the strict standards and regulations for presses. Not satisfied with simply meeting the minimum standards in this area, BalTec set itself the goal of achieving the highest performance level e (EN ISO 13849).

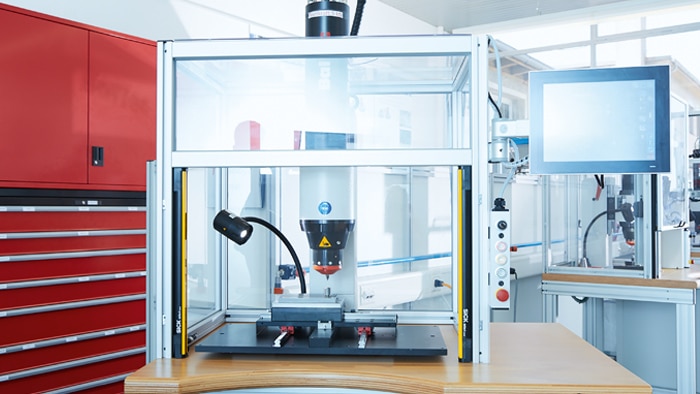

They therefore chose to use the deTec4 core light curtain, the STR1 transponder safety switch, and the TR10 Lock safety locking device from SICK. “Using these three systems for access protection, we were able to implement the highest standard of safety for every variant of the ‘Electric’, all from a single source. SICK also has an outstanding reputation in our European target market, which will help us during the market launch”, adds Huber.

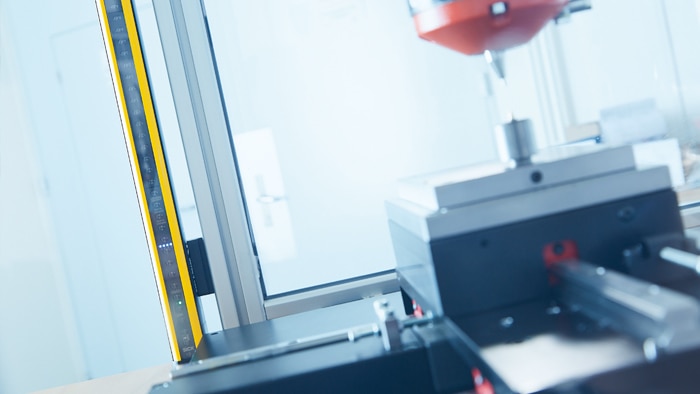

The absence of blind zones, in particular, is what impressed him first of all about the deTec4 core: “It enables me to successfully integrate the device into the overall concept and I consider it a great feature”. Its design was also a plus point for the esthete Klaus Huber, because: “There are some ugly light curtains out there too.“ He also praises the design feature of the deTec product family whereby the protective field height can be set in increments of 150 millimeters between 300 and 2,100 mm: “That was well thought out!” The short response time provided more de-sign freedom because it allowed the light curtain to be positioned close to the machine and an ergonomically satisfying workspace to be designed.

Short response times and successful design

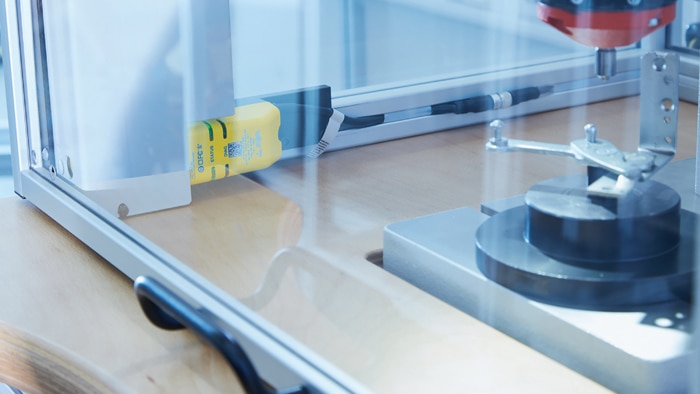

With short safety times of just 40 ms response time, 100 ms release time and 80 ms risk time, the STR1 non-contact safety switch has also been incorporated into the “Electric” with sliding table. It ensures a high machine availability thanks to a large door offset tolerance. The compact design again offers flexibility in mounting. As is also the case for the third access protection system from SICK, the TR10 Lock. Klaus Huber again praises “the successful design”, which for him goes hand in hand with its functionality: “The TR10 Lock can be integrated very attractively, its mechanical construction is fully reliable, and it performs its locking function with great strength and reliability without drill holes.” Furthermore, the high coding level of the actuator fulfills the requirements of EN ISO 14119 on manipulation protection without additional measures.

Three devices – one standardized interface

Three tried-and-proven products from SICK assume the safety tasks in the various machine variants of the “Electric” from BalTec. The advantages of a single supplier with complete solutions is obvious to Klaus Huber: “We have three different devices, but always the same standardized interface, which reduces the cabling work. It greatly simplifies the certification process and, last but not least, we have only one contact person for all matters.”

Good future prospects with the “Safety Assistant” app

BalTec regards the high cost and challenges of the intensive development process as a best possible investment in the future. “Internal value adding is very important to us, we are still in the early stages of marketing but expect that the productivity increase in the connection technology will become a key theme”, says Domenico Mollo. BalTec offers its own Human Machine Interface (HMI) dashboards for setting up the machine and supports its customers with a training session on the function of this interface. That SICK already offers apps for on-site diagnostics via smartphone for this NFC technology is of great interest to the Swiss machine builder in this regard and puts Klaus Huber at ease: “It’s good to know they already have that in their portfolio and I don’t have to go looking for a new supplier again.”

Read more:

The next step for safety: the deTec4 safety light curtain

Intelligent retrofit solution involving the Flexi Soft safety controller

Heiko Kahle

Head of Business Unit Light Beam Systems

Heiko Kahle har siden 2010 været leder af afdelingen Light Beam Systems hos SICK. Allerede siden 2000 blev diplomingeniøren i elektroteknik ansat i SICKs afdeling for Industrial Safety og varetog forskellige ansvarsfulde stillinger inden for produktadministration af optoelektroniske sikkerhedssensorer.