The Industrial Internet is only made possible thanks to intelligent, communicative sensors: With its Smart Sensor Solutions, SICK places great emphasis on the use of state-of-the-art sensor technologies in connection with complete integration into the control level via IO-Link. Particular attention in this regard is placed on the decentralization of certain automation functions into the sensor, both to ease the burden on the control and increase machine productivity.

Smart Sensors from SICK truly are intelligent: On the one hand, they facilitate complete transparency of the sensor functions and settings across all levels of the automation pyramid, while on the other, they take on certain automation functions that previously had to be programmed into the system control, taking real time and effort. As a result, the system control is capable of not only performing real-time diagnostics and flexible sensor configuration remotely, but this decentralization of the automation functions into the sensor also makes an active contribution to easing the burden on the PLC and increasing productivity.

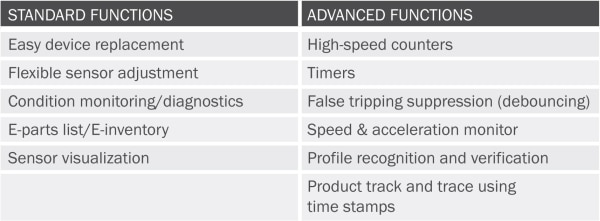

Smart Sensors Functions

Smart Sensors Functions

Innovative functions create added value

As a result, Smart Sensors can count process events independently, measure the time and speed of objects passing in front of the sensor, and even monitor rotational frequencies. The measured values detected by the sensor are either transferred to the control as an absolute value, or else the sensor performs the evaluation itself and outputs the appropriate binary information (e.g., process speed too low). This final point is even possible without IO-Link integration of the sensor.

SIEMENS, KHS uand SICK: Combined intelligence for sensors and controls

Example for Smart Sensor Solutions

Example for Smart Sensor Solutions

To demonstrate the capabilities of its smart sensors, SICK has joined forces with SIEMENS and KHS GmbH - a supplier of filling and packaging systems - to fully equip a system for attaching handles to various six-pack containers with the technology for Smart Sensor Solutions. Depending on how it is used, this technology offers significantly greater flexibility, operability, and efficiency, while optimizing the costs of the individual machine processes at the same time: (1) With the Time Stamp function, the WL12 photoelectric retro-reflective sensor carries out leading-edge and trailing-edge detection of a transparent six-pack on the feed belt. The switching information is transmitted to the control with the greatest precision in the form of a time stamp. (+) The advantage of this is that the control can use the time stamp - regardless of its cycle time - to control the MPA unit and pneumatic cylinder, which are also processed using Time Stamp, thereby perfectly synchronizing dynamic processes at high speed. (2) An MPA analog positioning sensor and pneumatic cylinder form a linear sensor system with the Time Stamp function. (+) The advantage of this is the activation of the pneumatic slide, which is timed with the greatest precision and triggered by the six-pack detection of the WL12 photoelectric retro-reflective sensor with the Time Stamp function. (3) The WSE4S-3 miniature photoelectric sensor with Timer function determines the time between the six-packs with the greatest precision and transfers these to the higher-level control when it can, although the timing here is not critical. (+) The advantage of this is that highly precise measurements can be taken while easing the burden on the control. (4) The WL4 photoelectric retro-reflective sensor with High-speed counter function is used for indirect measurements of the length of the unrolled transport belt via a breaker plate. (+) The advantage of this is that the unrolled length is checked directly in the sensor, so it is not necessary for the control to have a fast input card. (5) The inductive MultiTask sensor with speed and acceleration monitor (SAM) reliably monitors the belt speed by detecting the teeth on the gearwheel. (+) The advantage of this is the higher system throughput thanks to the use of a rugged and resistant inductive sensor as a cost-effective alternative to an encoder.

Example: Packaging machine

- Overview and product portfolio: Smart Sensor Solutions

- Download: Brochure "Smart Sensor Solutions powered by IO-Link"

- Overview: Industrielle Kommunikation und Geräteintegration