Equipping adjacent machines with only one safety component is extremely economical. In the context of the Scanner Plus! campaign, SICK has adopted this approach as a mission, developing the Sim-4-Safety solution based on the S3000 laser scanner and the Flexi Soft safety controller. The result constitutes the worlds first safety design that allows monitoring of up to four protective fields simultaneously.

More flexibility when operating adjacent machinery, better utilization of available space, complete integration of all safety components featured in a machine with short switch-off times, and high-level economic efficiency due to fast commissioning are the major advantages of the Sim-4-Safety solution.

Simultaneous safety for four hazardous areas

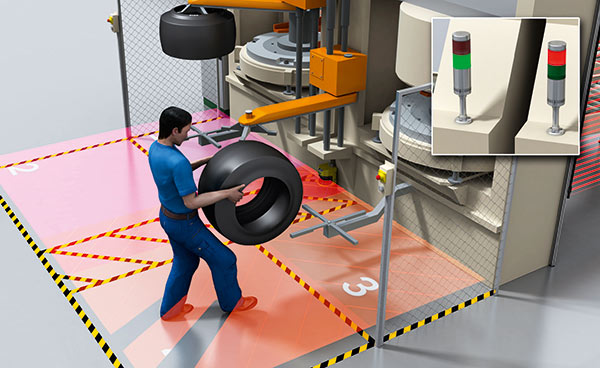

In many production areas, such as tire manufacturing, the process sequences allow operating several machines at the same time. For the first time, Sim-4-Safety now makes it possible to monitor up to four protective fields simultaneously using only one safety laser scanner, i.e. without protective field switching, thus avoiding superfluous safety shutdowns of adjacent machines. In this way, one can protect four hazardous movements, both of a machine as well as of adjacent parts within the installation. This ensures a maximum amount of flexibility when operating machines running side by side and production processes with minimum hardware effort invested.

Simultaneous monitoring: Faster and safer than sequential switching of protective fields

S3000 safety laser scanner

S3000 safety laser scanner

In the case of the S3000 safety laser scanner, monitoring of the simultaneous protective fields does not require control signals - in contrast to sequential switching of individual protective fields. Therefore, reaction time of the Sim-4-Safety is many times faster than in any possible system configuration involving other safety laser scanners on the market. In this way, the protective fields can be considerably smaller, designed for more efficient use of space. Due to the SICK-specific safe and easy-to-integrate EFI connection (= enhanced function interface), wiring effort is reduced to a minimum.

Flexi Soft manages the safe back four

Flexi Soft safety controller

Anything the S3000 detects using a scan is signaled by the safety laser scanner directly to the Flexi Soft safety controller. In this device, one can conveniently configure shutdown paths and shutdown behavior. Furthermore, the Flexi Soft is open to all safety sensors and safety command devices. In this way, it is possible to supplement the Sim-4-Safety functionality of the S3000 with additional safety-relevant signals as well as sensors that are not safety certified, such as photoelectric sensors and encoders, allowing implementation of a complete overall design. Sim-4-Safety enhances machine productivity while at the same time reducing commissioning and hardware effort.

- Product information: Sim-4-Safety & Scanner Plus!, S3000 safety laser scanner, Flexi Soft safety controller

- Product portfolio: Safety laser scanners, safety controllers