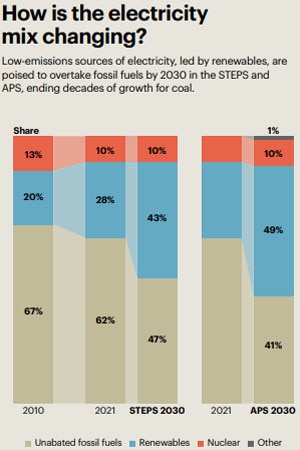

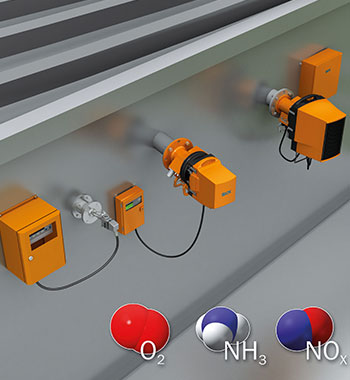

The decarbonization megatrend is causing evolutionary changes in the energy sector. Energy sources and the rate of used energy supplies are changing rapidly. We observe that existing power plants are modifying their combustion processes accordingly. Some energy companies are closing inefficient fossil fuel power plants and opening new plants based on cleaner energy sources. Alternatively, they invest directly in renewables.

Welcome to part three of our series on decarbonization where we focus on the energy industry.