When optical detection using point-shaped light beams reaches its limits, the light line of the WT14-2 photoelectric sensor and the light band of the Reflex Array MultiTask photoelectric sensor will carry the day. Significant enlargement of the detection surface makes it possible to compensate above all for the openings of printed circuit boards that vary in size. In turn, this results in reliable presence detection.

Rommel GmbH, a member of the Mühlbauer Group, specializes in turnkey solutions for the automation of production lines as well as for the marking and tracing of diverse products. In this context, one special segment is laser marking for traceability of safety-relevant components for the electronics industry. For example, one of the new products is the fully automated WL3000 LC laser marking station featuring an "inline" process. It enables only one machine to carry out double-sided marking of printed circuit boards in a single operation.

Reliable detection of printed circuit boards in laser marking stations

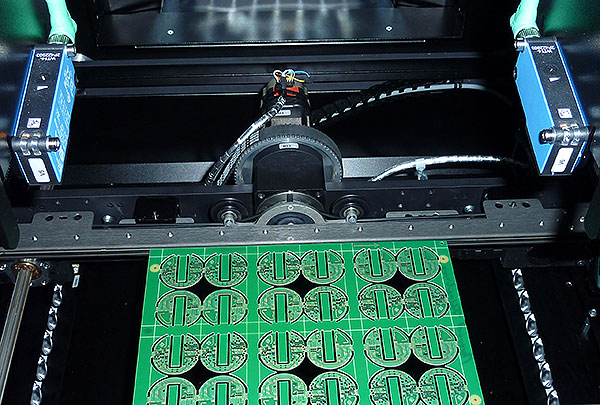

Prior to starting the different operations for marking printed circuit boards, it is necessary to check whether the printed circuit board is present. For this purpose, one uses a WT14-2P422S03 photoelectric sensor featuring a line-shaped light spot. Employing this solution means saving the reflector on the one hand and on the other hand, reliably detecting the printed circuit boards despite openings that vary in size. The point-shaped beam of a standard photoelectric sensor would pass through the openings in the printed circuit board, causing it not to be detected. In addition, the WT14-2P422S03 photoelectric sensor excels with an extended sensing distance.

The WT14-2 photoelectric sensor with line-shaped light spot checking the presence of printed circuit boards in marking systems

The WT14-2 photoelectric sensor with line-shaped light spot checking the presence of printed circuit boards in marking systems

Light band of the Reflex Array MultiTask photoelectric sensor improves checking for presence

The light band of the Reflex Array MultiTask photoelectric sensor

The light band of the Reflex Array MultiTask photoelectric sensor

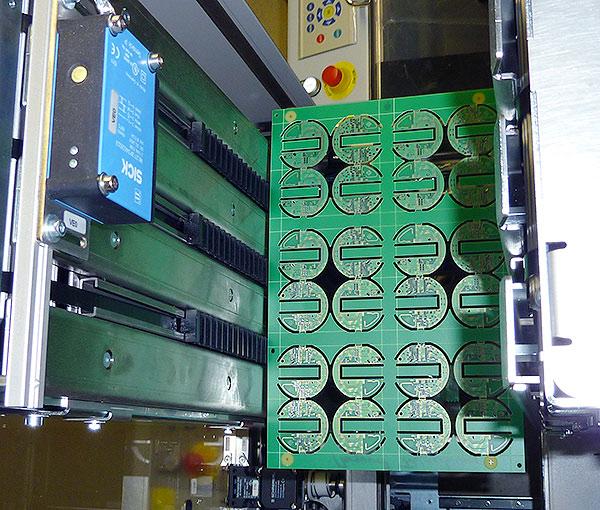

In buffer systems, several printed circuit boards are stored temporarily. As the printed circuit boards move into the buffer system, it is impossible to rule out that the printed circuit boards feature cut-outs or holes, respectively. During subsequent loading and unloading of the buffer system, this may lead to interruptions in production. Photoelectric sensors with a point-shaped light beam reach their limit in this respect as well, since the light beam passes through the openings in the printed circuit board that vary in size, thus failing to detect the printed circuit board. The reliable solution is detection using the Reflex Array MultiTask photoelectric sensor featuring a light band 50 mm in width and a sensing range of 2 m. This method compensates for and reliably detects larger openings in the printed circuit board. With its light band, the Reflex Array replaces several single sensors, each featuring one point-shaped light source.

The Reflex Array MultiTask photoelectric sensor checking for presence of printed circuit boards using the light band

The Reflex Array MultiTask photoelectric sensor checking for presence of printed circuit boards using the light band

- Product information: Reflex Array MultiTask photoelectric sensor, WT14-2 photoelectric sensor

- Product portfolio: MultiTask photoelectric sensors