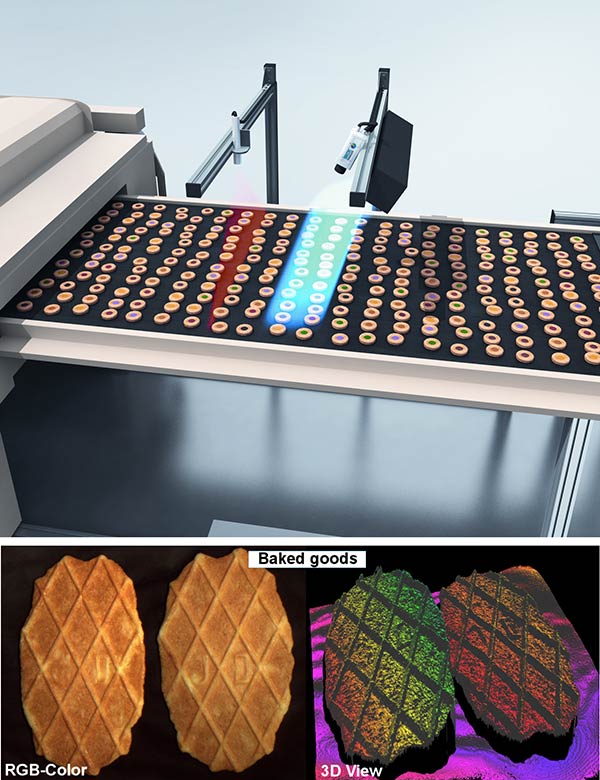

When it comes to foods, consumers primarily perceive the shape and color of the products as important indicators of quality. Broken cookies, missing frostings, or baking produce showing excessive browning - perhaps even in combination - suggest flaws in the production process. In their efforts to deliver only impeccable, high-quality goods to retail stores, a growing number of producers rely on inline inspections of shape and color using the ColorRanger E 3D color camera.

ColorRanger E: more system performance requiring fewer system resources

The ColorRanger E from SICK is a high-speed 3D camera featuring high-performance and high image quality. The camera can be configured easily for simultaneous multiple measurement of 3D contours and colors or gray values. RGB signal with a resolution of up to 3,072 pixels per channel, fast and precise 3D data as well as the scanning frequency of up to 11 kHz via Gigabit Ethernet interface allow for parallel multiple inspections at full production speed. In this way, a single ColorRanger E replaces several other cameras, significantly reducing system size and costs for hardware, integration, and maintenance

The ColorRanger E from SICK is a high-speed 3D camera featuring high-performance and high image quality. The camera can be configured easily for simultaneous multiple measurement of 3D contours and colors or gray values. RGB signal with a resolution of up to 3,072 pixels per channel, fast and precise 3D data as well as the scanning frequency of up to 11 kHz via Gigabit Ethernet interface allow for parallel multiple inspections at full production speed. In this way, a single ColorRanger E replaces several other cameras, significantly reducing system size and costs for hardware, integration, and maintenance

High-speed inspection permits high-speed rejection

In the food industry, inspecting the shape of baked goods and the degree of browning ranks among the frequent applications of the ColorRanger E; so is the assessment of meats, fruits, or vegetables. In order to reject flawed products even on the production line, Adbro Controls Ltd. has developed a high-speed ejection system featuring an integrated ColorRanger E, an arrangement that reliably detects even flaws measuring only 0.3 mm. The camera transmits the captured data pertaining to shape and color to a host PC that compares them to the saved reference samples. In case of a not correct signal, pneumatic nozzles are activated, blowing the flawed item from the belt using compressed air. At the same time, the PC saves the data, further processing them into statistics and trend information that allow for early intervention in case of production errors emerging, e.g. breakage or excessive browning of baked goods.

ColorRanger E, the camera design that increases quality and reduces costs.

- Product portfolio: 3D cameras