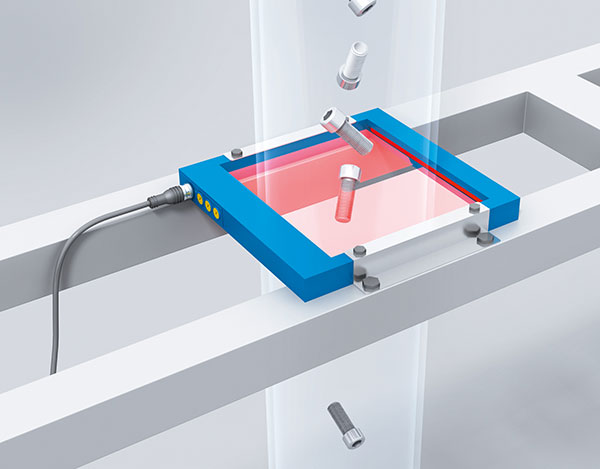

The new FLG (Frame Light Grid) standard automation light grid from SICK is a precise, installation-friendly solution for detecting free-falling objects. By way of example, the "Frame Light Grid" is used for ejection detection and parts counting as well as a pick-to-light sensor.

The FLG is a one-way system in which the sender and receiver are permanently installed in a frame. It is available in three sizes for three different detection ranges and can detect small items down to 2 mm in size.

So easy to integrate

Because the sender and receiver in the FLG are fixed in place at the factory and directed towards each other, the time consuming installation and adjustment at the point of use is no longer necessary. This also applies to the "open" fork-type sensor version of the FLG. Setting of the sensitivity, the operating principle, e.g. counting in the dynamic mode or filament break control in the static mode, or pulse stretching is done directly at the sensor. An integrated key guard protects against unwanted parameter changes during operation.

The sensor solution - and more - for free-fall object detection

Even if it has to run quickly due to large numbers of items, the FLG picks up everything that falls through the frame: metal parts from punch presses, rejected parts on conveyor systems, tablets in the primary packaging of pharmaceutical products or screw caps from drinks container filling. Furthermore, the sensor is a solution that is easy to install for pick-to-light access control. In static operation, it can also be used to monitor thread or cable breaks.

The Frame Light Grid - the new "framework program" for free-falling parts and more.

- Product information: FLG standard automation light grid

- Product portfolio: Standard automation light grids