WTB12-3 Line photoelectric proximity sensors from SICK ensure 100-percent counting reliability in the counting and weighing machines for baked goods made by A&B Verpackungsmaschinen Manufaktur GmbH. Every hour sees the production of up to 100,000, rolls, croissants, pretzels, and other baked goods.

Hand-made in Germany: packaging systems from A&B

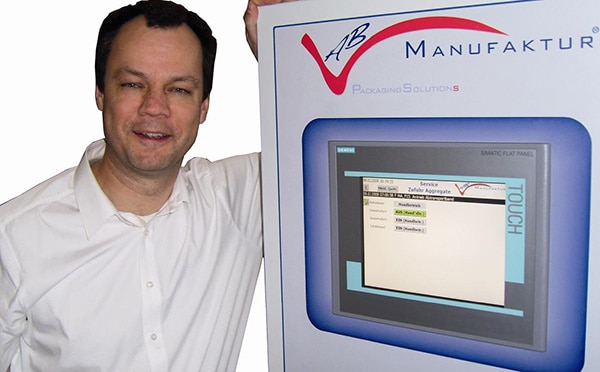

A&B Verpackungsmaschinen Manufaktur GmbH based in Horst (Schleswig-Holstein) specializes in the planning, development, manufacturing, and installation of automated packaging systems, specifically for the food-processing industry. The high-performance counting and weighing machines of the TK series from A&B are used for counting, weighing, and conveying of baked goods. The machines easy-to-clean CLEANDESIGN is convincing due to excellent workmanship using stainless steel and food-safe plastics. Weighing buckets in staggered position and minimized drops from the vibration channels into the buckets ensure careful handling of products.

Great variety of baked goods: correct counting is what counts

Whether fully baked, partly baked, or as a piece of dough - depending on the machine design, it is possible to process up to 100,000 croissants, rolls, pretzels, pretzel sticks, bagels, or other baked goods. This is where the challenge lies: The surfaces of certain baked goods and types of dough, some of them shiny or crystalline, may cause the reflection from the target object to the sensor to go missing in photoelectric sensors featuring a conventional light spot. With a view to the diverse processing and packaging steps, it is absolutely imperative to avoid such blackouts, says Bernd Affeldt, General Manager of A&B.

Bernd Affeldt, General Manager of A&B[/caption] It is the 100-percent detection quality of SICKs photoelectric sensors that endows our counting and weighing machines with up to 10 percent more throughput performance as opposed to comparable systems from other manufacturers."

Bernd Affeldt, General Manager of A&B[/caption] It is the 100-percent detection quality of SICKs photoelectric sensors that endows our counting and weighing machines with up to 10 percent more throughput performance as opposed to comparable systems from other manufacturers."

WTB12-3 Line: reliable in detecting, all the way down the line

WTB12-3 Line

WTB12-3 Line

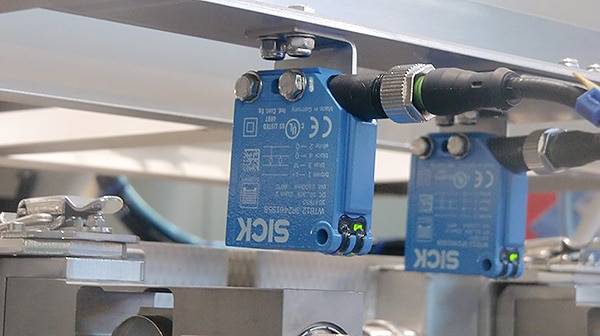

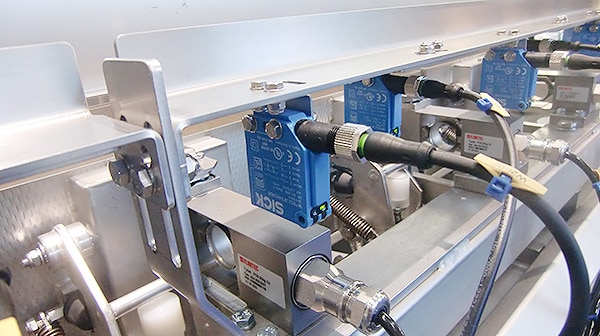

photoelectric proximity sensor

The WTB12-3 Line photoelectric proximity sensor from SICK is the perfect solution for this task. Featuring a line-shaped light spot, the sensor is capable of generating diffuse reflections suitable for evaluation even with respect to shapes curved in any possible way. In this way, the device can reliably detect, for instance, products with inhomogeneous surfaces or inaccurate positioning. In addition, precise background suppression prevents adverse effects due to reflections and optical sources of interference from the background of the machine. Influences from electromagnetic sources or high-frequency lamps are suppressed dependably as well, thus achieving reliable detection behavior. To enable A&Bs end customers to utilize the high process reliability of the WTB12-3 Line even under the harsh operating conditions of automated large-scale baking lines, the photoelectric line sensor features a rugged metal housing. High-pressure washing, cleaning and disinfecting agents, or temperature fluctuations from 40 °C to +60 °C do not impair the sensor function either, since the sensor was designed for this very purpose.

This convincing performance in practice has resulted in A&B now using the WTB12-3 Line throughout as a standard sensor in this type of facility.

This convincing performance in practice has resulted in A&B now using the WTB12-3 Line throughout as a standard sensor in this type of facility.

- Product information: WTB12-3 Line photoelectric proximity sensor

- Product portfolio: Small photoelectric sensors