Communication with ORiN standard middleware specification possible

What is ORiN?

ORiN (Open Robot/Resource interface for the Network) is a standard middleware specification developed for systems in factory automation. ORiN2, the second version of this specification, offers a standard interface for applications, sensors, controls and data schemes including standard communication protocols. Provider modules (expansion modules), which are created based on this specification, enable standardized access methods for different devices. This makes it possible to improve the reusability and reliability of IT systems in a factory, to shorten system development times and achieve quicker implementation.

ORiN-compatible add-ins are used in the robot controls so that external devices such as PLCs, cameras or sensors can be used with common interface specifications. These add-ins are referred to as providers. SICK has recognized the benefits of ORiN and expanded its extensive range of sensors for robotics to include a first provider for the PLOC2D robot guidance system.

The benefits of ORiN

For end users:

- A manufacturer-independent system environment which is easy to create

- Option for process monitoring and remote maintenance of the production line

For system integrators:

- Easy integration of the PLOC2D robot guidance system into the robot system

- Quick commissioning with the use of the standard ORiN interface

- Minimum programming effort with ORiN provider (DDL libraries)

For device manufacturers and OEMs:

- Shortening of processes in the development of communication interfaces and tests

- Collaboration with other manufacturers

Examples of solutions

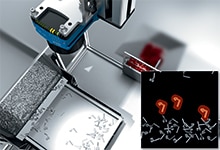

Part localization in the AnyFeeder

An AnyFeeder machine conveys and flips small parts without refeeding and without the use of conveyor belts. In this case, small parts are randomly aligned. The PLOC2D robot guidance system quickly and reliably detects their position and transmits position data and orientations to the robot control system using the ORiN provider. Thanks to the standardized ORiN interface, smooth communication between the PLOC2D and the robot control is guaranteed. Using the recorded information, the robot is able to pick up the properly aligned parts and feed them to the next process. Incorrectly aligned parts are ignored and realigned by pulsed vertical oscillations after the properly aligned parts are picked up.

Products

Working together as equals

Thanks to sensors from SICK, robots perceive more precisely. For all challenges in the field of robotics: Robot Vision, Safe Robotics, End-of-Arm Tooling, and Position Feedback.

Learn more