The ability to provide the right solution in virtually every industry all over the world requires a global presence, application knowledge, and a broad product portfolio. In an ideal scenario, all of these elements are incorporated into tailored complete solutions, which are then standardized, reproduced, and used in other areas. A global presence and efficient, comprehensive support are becoming more and more crucial in this regard.

From process automation and factory automation to logistics automation: System solutions from SICK are based on widely used components, comprehensive application knowledge, and internationally available services. From standardized products to individual customer wishes, the on-site collaboration between clients, industry experts, and product specialists from SICK results in practicable, scalable solutions.

Lector65x System: Focusing on a huge range of applications

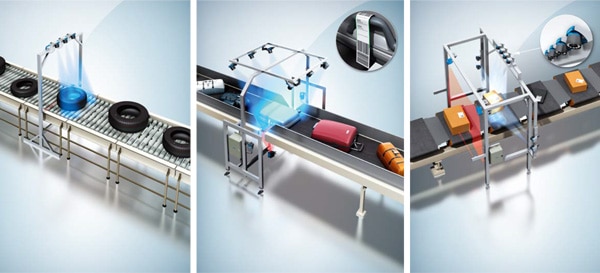

Based on the Lector65x image-based code reader, the track and trace system reliably identifies and decodes all common types of codes. In addition, the high-resolution images can also be used for video coding and OCR tasks. The type of camera (fixed or dynamic focus), the number of cameras, and the camera alignment are individually tailored to the application in question by SICKs project managers - from reading the top side of parcels or tires to 5-sided reading of parcels or flight luggage. The Lector65x System can also be cleverly combined with other technologies such as ICR8xx line-scanning cameras, volume measurement systems, laser- based code readers, or weigh scales. The Lector65x System has a lot to offer - from a simple, cost-effective system to a tailored complete solution.

One system solution - many applications: Reliable Identification and track and trace for tires, flight luggage, or parcels with the Lector65x System

One system solution - many applications: Reliable Identification and track and trace for tires, flight luggage, or parcels with the Lector65x System

SCR bypass - reduce harmful emissions and much more besides

Modern power plants employ efficient flue gas cleaning systems. The Selective Catalytic Reduction, or SCR, method is used as a secondary measure to reduce nitrogen oxides. Thanks to the innovative SCR bypass measurement solution from SICK, modern power plants can now reduce more than just harmful emissions. Within the process itself, this measuring technique makes it possible to maximize catalyst lifetimes, minimize ammonia consumption, and obtain pure gypsum with minimum NH3 content - ideal for further use.

The measurement solution consists of gas analyzers and flow meters from SICK. The GM32 in-situ UV gas analyzer measures the proportion of nitrogen oxide directly in the special bypass system cell. Air is used to keep the analyzer lens cool and free of dust. The measurement result enables the injection of ammonia to be regulated precisely, while the FLOWSIC100 volume flow measuring device measures the mass flow rate using ultrasound. The flue gas is analyzed again at the SCR output. If nitrogen oxides are still present, more ammonia is added. If there is too much ammonia in the gas, the injected amount is reduced accordingly. The GM700 laser gas analyzer is an additional unit on the outlet skid that precisely measures the ammonia slip and moisture content. One of the key innovative elements is the sampling system itself. A large number of sampling lances (usually eight), each with around four to eight sampling openings, are used to take a representative sample of the measurement gas along the entire cross section. As windrows often form, the measurement and control will not work correctly if the measurement is only taken at one point.

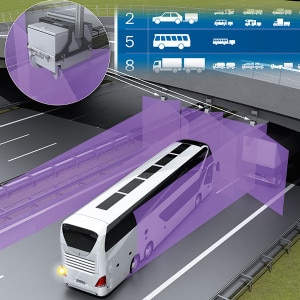

TIC Pro profiling systems - reliable vehicle classification, axle counting, and vehicle counting

The systems in the TIC Pro (Traffic Information Collector) product family have been in use for years across the different continents. They are used on roads to record information about vehicles, traffic flow, and traffic composition. The laser scanners scan the road up to 100 times per second. The system then uses this measurement data to generate a 3D model of each detected vehicle via the integrated controller. In a subsequent step, these models can be divided into up to 30 vehicle classes using classification algorithms. TIC Pro is automatically calibrated during flowing traffic and provides an integrated remote maintenance function.

- Product information: Lector®65x system, In-situ gas analyzers: GM32 UV, GM700, ZIRKOR302,

gas flow measuring devices: FLOWSIC100 H, FLOWSIC100 M-AC, Traffic Information Collector TIC102 - Product portfolio: Track and trace systems, Collision awareness systems, Analyzer systems, Object Detection Systems, Profiling systems, Security systems, Robot guidance systems