Agricultural machines are exposed to extreme situations which require a high degree of ruggedness to withstand. Only the tough - and the giving - prevail. IMB inductive proximity sensors make a major contribution to this. With a rugged stainless-steel housing, special seals, the latest ASIC technology from SICK, and the wide temperature range unique to the market, they ensure process stability, even under very difficult conditions - and cover a wide variety of applications while doing so.  Inductive proximity sensors from SICK withstand icy cold and extreme heat, and work reliably even in the event of strong vibrations. The sensors effortlessly resist both frequent contact with water and aggressive oils. When push comes to shove, inductive proximity sensors from SICK achieve top performances. The sensors are characterized by a high processing quality, a long service life, and extreme ruggedness. Modern ASIC technology guarantees the highest level of precision and reliability in their performance. Metallic objects are detected entirely without contact via a high-frequency electromagnetic alternating field. The IME inductive sensor from SICK has already been established as an economically efficient standard in industrial environments.

Inductive proximity sensors from SICK withstand icy cold and extreme heat, and work reliably even in the event of strong vibrations. The sensors effortlessly resist both frequent contact with water and aggressive oils. When push comes to shove, inductive proximity sensors from SICK achieve top performances. The sensors are characterized by a high processing quality, a long service life, and extreme ruggedness. Modern ASIC technology guarantees the highest level of precision and reliability in their performance. Metallic objects are detected entirely without contact via a high-frequency electromagnetic alternating field. The IME inductive sensor from SICK has already been established as an economically efficient standard in industrial environments.

A rugged design is essential

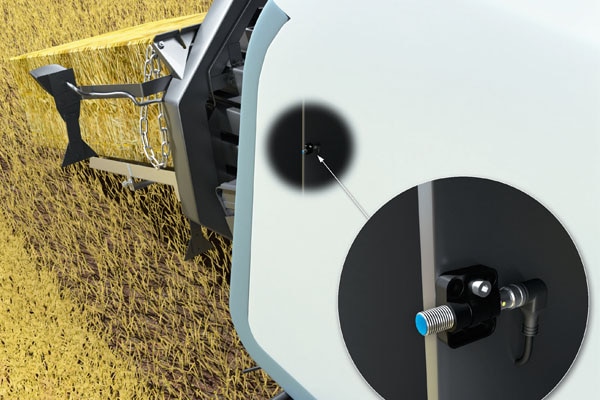

What the IME has started on a small scale in factory automation, the new product family of IMB inductive proximity sensors is continuing on a large scale - with a combination of properties which specifically tailors the sensor to the challenges of outdoor mobile automation. In addition to the rugged stainless steel housing, the catalog of features includes self-locking nuts with O-rings for protection from ambient conditions. Another feature is the temperature range which is unique to the market and allows for the IMB to be used in temperatures between -40 °C and +100 °C. the temperature range from -40 °C to +100 °C in which the IMB can be used; this range is unique to the market. It is armed against all eventualities: It withstands extreme temperatures and weather, is resistant to lubricants, oils, and fertilizers - and is unyielding against mechanical loads.

Where there is movement, there is a sensor

The field of application of the inductive sensor in agricultural and forestry machines is wide and encompasses every element of movement of the mobile application: Generally speaking, that means the entire spectrum of speed and position detection, including the central task of individual position and end position detection of mechanical components. In detail, it means the successive documentation of all process steps. The IMB inductive sensor is thereby deeply anchored in the core of process automation of the respective application and is a central key component on the path from hydraulic-mechanical to highly-automated operations of the future.

Exact process control

In practice, numerous sensors master the complex field of detection and positioning tasks - up to 30 IMB inductive proximity sensors are used on a baler, for example. Pressing straw into a bale requires many process steps which the IMB monitors - from the pre-press to the press shaft to the main press, and from axis monitoring to the position query of all dynamic components and end positions. In all this, the IMB takes advantage of its properties with consistency: Wide and high-precision sensing ranges enable exact process control. Thanks to its stable and long-lasting housing, the inductive sensor reduces machine downtime, which is important in peak harvesting phases, for example. A visual adjustment indicator, self-locking nuts, and individually-designed connectivity ensure quick and easy sensor installation on-site. Last but not least, the IMB is available off the shelf worldwide for a short time, and the maintenance work for the sensor is minimal. All this makes the IMB the ideal partner for countless automation applications

- Product information: IME, IMB

- Product portfolio: inductive proximity sensors