The safety light curtain is relied on to protect the safety of factory personnel all over the world. Yet, although the technology was developed almost 70 years ago, many applications may still not be making full use of its capabilities. I have tried to re-appraise what light curtains could be contributing to your machinery safety, factory control, and productivity with a breakdown of the functions and features that are currently available. The light curtain has become so ubiquitous, that it is all too easy to regard it as a simple on/off device - a fail-safe, fit-and-forget substitute for protective fencing. However, an expanding and versatile range of light curtains has evolved to perform multiple functions and they can contribute positively to productivity and integrate with factory local area networks to support better plant-wide automation.

What exactly is a safety light curtain?

History of the light curtain

In 1951, Erwin Sick presented the first wooden model of his light curtain to the “German Inventor and New Development Trade Fair” in Munich. Later the same year a patent registration of the light curtain based on the autocollimator principle was regarded as the technical breakthrough that began the development of technology we know today – one that has saved countless people from injury and death at the hands of dangerous machinery. Since that time, hardware and software development have transformed the versatility and use of safety light curtains. The key attributes of light curtains remain the same, but their potential may still be under-exploited.

Light curtain specifications

There really is no such thing as a straight like-for-like off the shelf ‘menu’ of safety light curtains since all manufacturers offer their own ranges including different sizes, shapes, and resolutions etc. However, the starting point of any safety application is always the danger you want to guard against and the space that it is in. Based on this, there are different attributes to consider regarding the physical properties of the light curtain. Currently, the document EN ISO 13855 is the harmonized standard for positioning Safety light beam systems, and it can assist in determining which of these physical attributes to go for and in this section I have tried to explain the main specifications to consider. However, there are also additional properties such as IP rating, current consumption, visible indications etc. that are not covered here.

Scanning range

The range is the maximum distance between sender and receiver. In case of active / passive units the distance between the active part and the passive part is called scanning range, too. Products are available with either a fixed range, a selectable range (e.g. low/high) or they have an auto-adjusting range (at start-up, the sensitivity is adjusted based on the distance between sender and receiver). Choosing the correct range ensures that the Safety light beam systems is best fit for the application, for example, if a high power, long range, device is used over a short distance, reflections off nearby surfaces may make the installation unsafe. On the other hand, a long range device may be required for protecting large areas which require high beam.

Protective Field Height

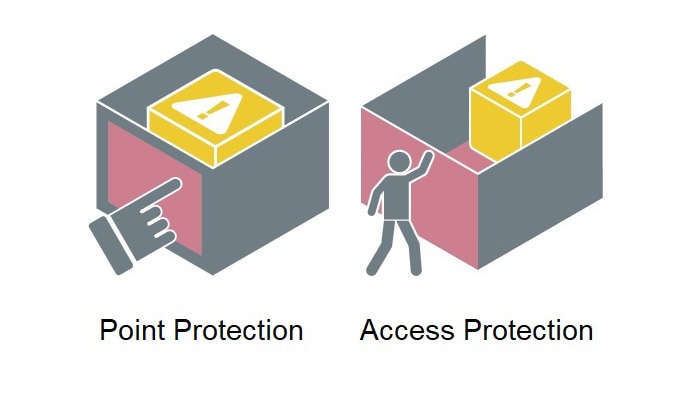

The height of a Safety light beam system must be chosen based on the access to the hazard. For example if a light curtain is protecting against "point protection" then the light curtain must cover the whole aperture. However, if the Safety product is for access protection then different heights can be used based on the number of beams required and the height from the floor plus possible reach over.

Resolution

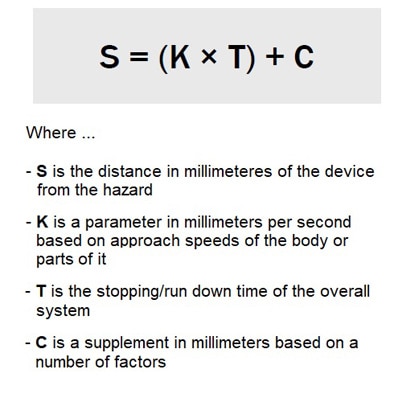

The resolution of a light curtain can also affect the mounting position with respect to the hazard. The terms “finger protection” and "hand protection" are often used which refer to resolutions of 14 mm and 30 mm respectively. However, light curtains and multiple beam systems can also have different resolutions or beam separations (e.g. 20 mm, 40 mm , 200 mm etc.). The higher the resolution, then the better the detection capability is for a safety light curtain and therefore the device can be mounted closer to a hazard (i.e. a 14 mm light curtain can be mounted closer than a 30 mm light curtain). EN ISO 13855 contains lots of different calculations for mounting distances and resolution can have a large impact but the basic equation is, figure 2:

The standard also covers additional things such as direction of approach, possible reach over etc. For larger distances and access protection a beam separation of 400 mm is normally sufficient, but then additional devices may be required for presence detection if the machine can be reset whilst a person is behind the light curtain or multiple light beam safety device. A thorough risk assessment according to the harmonized standard EN ISO 12100 should be performed to take these points into consideration. Higher resolution light curtains are usually more expensive than lower resolutions, but switching to a lower resolution means that the distance between the safety light curtain and the hazard needs to be increased which may be impractical or not possible on the factory floor.

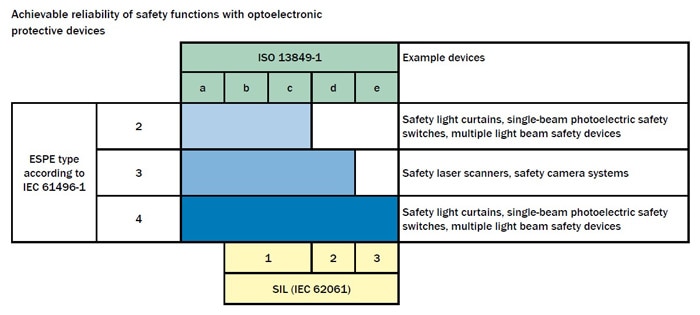

Type

When choosing a safety device for an application, the harmonized standard EN ISO 13849 or IEC 62061 can be used to design the safety related parts of the control system (SRP/CS). Following the definition of a safety function (e.g. initiating a stop using a safety light curtain) it is important to determine what performance level (PL) or safety integrity level (SIL) that the associated SRP/CS should achieve based on the risk. I will not go into detail about functional safety here but for electro sensitive protective equipment, the Safety light beam systems according to IEC 61496 is directly related to what PL/SIL that the safety function can achieve. The following figure reflects the relationship, figure 3.

Therefore if PLe/SIL3 is required, for example for protecting power presses, a type 4 device would be required.

Active/passive systems

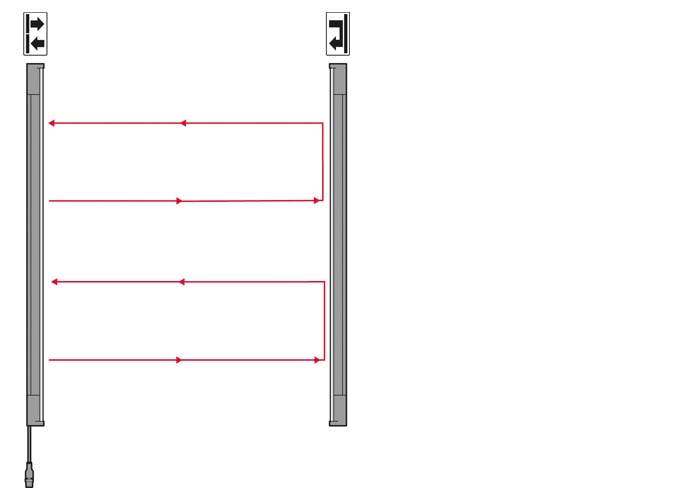

To save on wiring and to keep costs down for access protection applications, active passive systems can be used. An active/passive system consists of two devices. One device contains both emitting elements and receiving elements and the other device contains e.g. mirrors that are used to deflect the beams back to the receivers, figure 4. Mirrors reduce the strength of a light beam and therefore active/passive systems will normally have a much shorter distance than sender/receiver systems.

ESPE Functions of Safety light beam systems

The simplest function of a light curtain is when light beams are obstructed and the outputs turn off, which signals a stop to the associated hazardous movement(s). If no incident has occurred and the area is safe, a reset can be performed. This stop/start style of safe operation can be disruptive to factory flow and productivity and therefore the light curtain has evolved over the last half century to perform multiple functions such as internal reset, external device monitoring (EDM), beam coding, muting, blanking, pattern recognition and beam coding.

Restart interlock

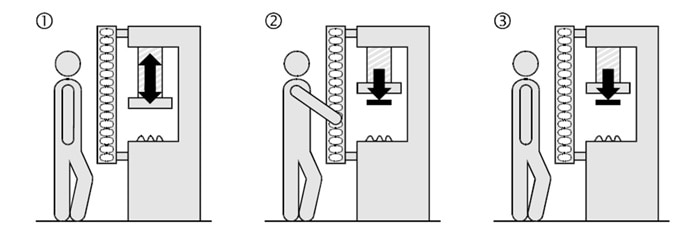

The two main interlocking modes that can be set in are automated – Output safety switching device (OSSD’s) go high when the beams are free. Manual – OSSD’s go high when the beams are free and then a reset button is pressed. It is important that an automated restart can only be used in specific case when it is not possible to stand behind the light curtain without being detected (e.g. small press with arm only access), figure 5. Further requirements may also apply.

A manual reset can be performed using either an external safety relay, safety PLC or internally if the Safety light beam systems has the capability. Before safety PLC/Relays the reset was performed using relay logic.

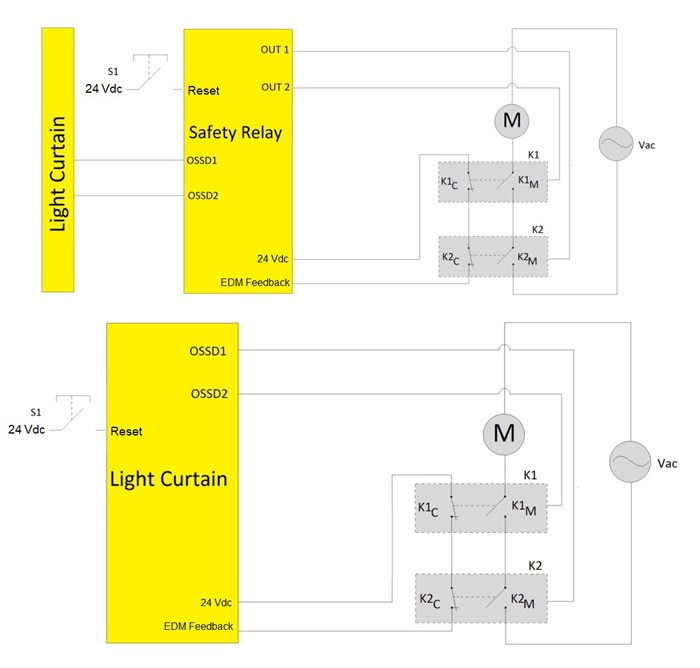

Eternal Device Monitoring (EDM)

The level of safety performance for a safety function can be increased if fault detection is implemented. The harmonized standard EN ISO 13849, which is used for calculating performance level of a SRP/CS describes the term diagnostics coverage (DC) which measured this capability. It is a measure of how many dangerous failures are detected. One method, listed in these standards and used extensively in industry, has a diagnostics coverage of 99% (can detect 99% of dangerous failures) and is called External Device Monitoring (EDM) or “check back.” This monitoring function is a means in which a safety device actively monitors the state of external devices that it controls such as machine primary control elements (MPCEs), contactors, or relays. This is needed because the external devices usually have no diagnostics of their own. If an unsafe state is detected in the external device then the safety device can lock out. This is performed by monitoring complimentary channels of the external devices which are physically linked internally. If the outputs of a safety device go high, the returning EDM signal from the final switching devices must go low if the system is in a safe condition. Otherwise, there is a fault. See Figure 6 for examples of implementation in a safety relay and directly in a safety light curtain.

Blanking

In some applications, it might be desirable to permit certain objects to protrude through the light curtain field without signaling an obstruction of the detection zone. For example, when using a support table or rack required to feed the machine with a heavy work-piece, a blanking feature can be applied to modify the detection capability of the light curtain and not interrupt the work flow. The blanking can either be fixed or floating to allow a variable position for the object. See Figure 7.

Enabling Material Throughput - Muting

In many applications of Safety light beam systems, the safety device must be able to allow objects through whilst still reacting to presence of people. This is particularly important on conveying lines with goods passing from one area of production to another or in automated warehousing operations where staff are excluded from the automated stacking and shelving areas.

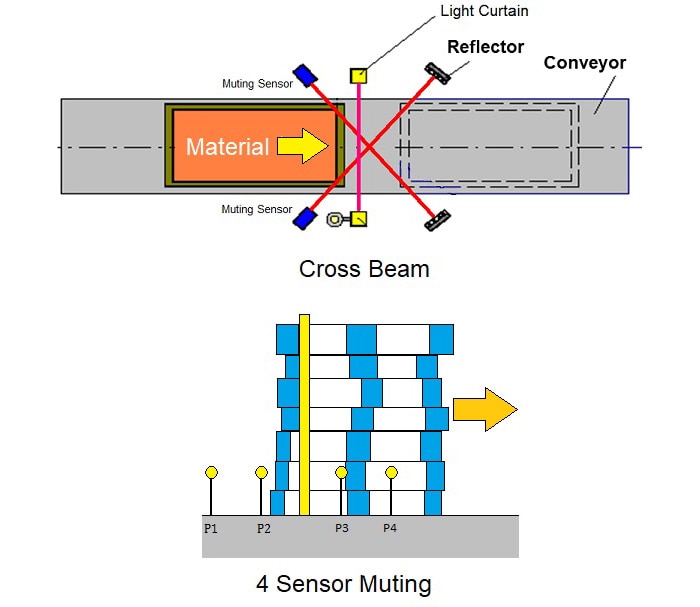

Sensors can be used to identify the object (such as a car body) and allow passage in to a hazard zone due to the shape and size, while still detecting presence of a person. This is automatic and known as muting. The two most popular methods of muting are cross beam and four sensor muting, as shown in Figure 8.

However, there are many different methods of muting including the use of photocells, ground inductive loops, the use of safety laser scanners, partial muting (partial blanking) etc. The technical specification IEC/TS 62046 can assist in the application of protective devices to detect persons. It is important to understand though that muting is not the same as bypass - muting is automated whilst bypass is a mode selected by an operator whilst other protection measures (e.g. enabling device) i.e. manual.

Another term related to muting is "override" which is a manual triggering of the muting after an error in the muting conditions. This is needed to make a system clear for example when a pallet is stuck in a safety light curtain which has stopped the conveyor and the conveyor temporarily needs power to remove the pallet.

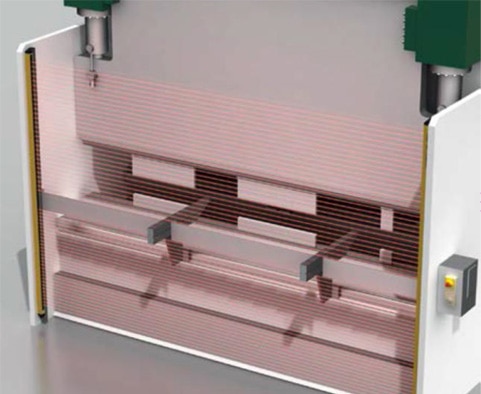

Enabling Material Throughput - Pattern Recognition

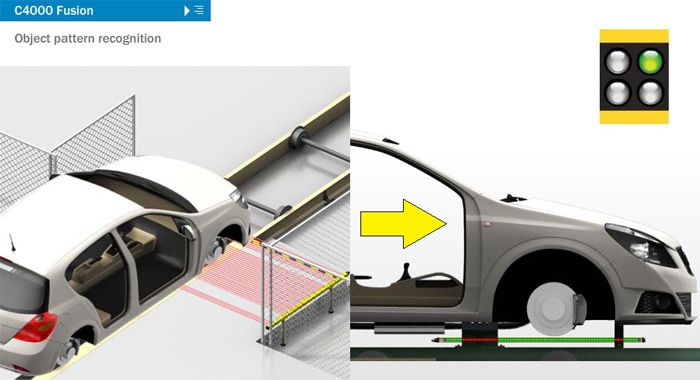

There are some safety light curtains that can perform complex algorithms on individual beams. This means that not only can it detect if the beams are obstructed or not, but also which beams and in which sequence.

The light curtain can safely detect patterns, objects, and direction, maintaining the safety while still allowing known patterns to enter and leave the detection zone of the light curtain. Furthermore, it does not require any additional sensors or control. This powerful function can dramatically increase availability and increase safety while at the same time as allowing material to pass through. The C4000 Fusion is an example of such a device. See Figure 9.

Beam coding

Because andmultiple beam systems work over similar optical frequency in the Infra Red spectrum, if several safety light curtains are used in close proximity interference can occur between the systems. This could cause a dangerous situation. To overcome this some safety light curtains offer beam coding so that a receiver can distinguish the beams from a specific sender and not be affected by another device in close proximity. When beam coding is activated though, this may affect the response time and/or range of the safety light curtain and should be taken into account as this may affect the mounting distance.

Summary: What are safety light curtains and multiple light beam safety devices

Today’s Safety device installations are much more attuned to production needs, capable of a wide range of manual and automated actions that ensure a Safety light beam systems assists safety and productivity rather than sacrificing efficiency. However, it is important to know what features and functions are available on a safety light curtain and also if the application requires them or not? Safety light beam systems. The application of a Safety product is not always as straight forward as sticking it in front of an access point and further thought may be required.

Read more

Martin Kidman

Product Specialist Machinery Safety SICK (UK) Ltd.

Martin Kidman gained his Ph.D. at the University of Liverpool in 2010 and has been involved in Industrial Automation since 2006 working for various manufacturers of sensors. He has been at SICK UK Ltd. since 2013 as a product specialist for machinery safety providing services, support and consultancy for industrial safety applications. He is also a certified Functional Safety Engineer (TUV Rheinland, #13017/16).