FPC Food Plastics was struggling to look down the neck of every bottle in an attempt to identify discolored stock. What they needed was an optical solution.

Turnkey vision solution: Looking down the barrel of a bottle

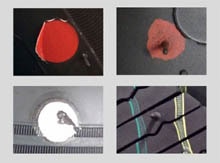

As a primary supplier of cap closures and bottles, Australian brand FPC Food Plastics (FPC) has been supplying bottling services to the dairy, fruit juice and food service markets for more than 20 years. With a focus in dairy, its bottles range from 150ml to 5 litres in capacity. The issue FPC plastics was facing was a yellow tint that became more saturated at the base of the bottles. FPC needed a reliable system that could detect this issue and remove it from the production line.

“The yellow tint had been occurring infrequently,” said Patrycja Chrobak, quality manager at FPC. “It was mainly due to issues with the grinder that happened between batch productions. Even with procedures and regulations in place, we still saw a small number of bottles with this yellow tinting. The difficulty was that the discoloration was so small that we weren’t too sure how to consistently stop this issue from occurring again,” said Ron Woolard, site electrician at FPC. “If you put a product within specification and the discolored product side by side, it’s extremely difficult for the human eye to detect.”

Due to the limitation and high cost of human inspectors, and the demand of reliable and consistent checking abilities that human labor simply couldn’t satisfy, the team knew they needed to turn to machine vision. The idea to introduce sensors as a solution came during one of FPC’s team quality meetings. “I knew SICK was a leader in optical sensors,” said Woolard. “Having worked in this industry for quite a while, I’d encountered them a lot and previously used their equipment across different jobs.” Once contacted, SICK asked for samples to get a better idea of the extent of the issue and the quality of camera that would be needed. As a global manufacturer of sensors and sensor solutions for industrial automation applications, SICK was able to come back with a solution for the company.

High-quality optical machine vision with midiCam

“SICK was able to sort us out with a package,” said Woolard. “Rather than selecting products we weren’t entirely sure about, we simply gave them the problem and they came back to us with a turnkey solution.” The solution was SICK’s midiCam, designed specifically for complex image processing tasks, such as FPC’s issue with bottle discoloration. The camera was easy for the FPC team to plug-and-play and combined with the provided photoelectric sensors was able to provide high-quality optical machine vision.

SICK also provided a Sensor Integration Machine (SIM1012) and sensor display screen (SID120) along with power supplies and an external pilot light. The sensor machine allowed interface between the camera, illumination and sensors to ensure the process ran smoothly while the integration display screen worked to integrate all the data into a visual display.

Digitalizing the process helped identifying bottle discoloration

“The process really started with one of SICK’s technical sales specialist, Amit Shinde, who was instrumental in getting the project started, organized the personnel to work on the project and keep it on budget,” said Woolard. With contact beginning in mid-July last year, the entire process was finished by March 2021. After FPC set up the equipment, two more installation specialists came out to ensure that the adjustments and setup were correct and to coordinate the devices. “They even brought their own lunches,” recalled Chrobak laughing. “They were so committed, staying at least four to five hours adjusting everything.” The final setup looked like a photoshoot for bottles. Since the bottles would be moving along the conveyor belt at a rapid pace, a light source was needed to identify the discoloration in a short period of time.

“What we got from SICK was a box of parts, including a large screen, mounts for the camera, and bright lights to highlight the bottles,” said Woolard. “The lights provided the brightness and short exposure we needed.” The camera was set 140mm above the bottle and specifically adjusted to pick up yellow tones. Its hue was set to specific level with minimal tolerance allowing the camera to pick up more pixels in bottles that had the yellow discoloration, which was how it distinguished between “pass” and “fail” bottles. Since the bottles were on a conveyor belt, illuminating the bottles from below wasn’t an option. Instead, the light was placed on the side of bottle, focusing on the lower portion. This setup enabled FPC to digitalize the process of identifying any bottle discoloration. “There’s now no need to have a person standing on the production line, looking down the neck of every bottle just to spot the issue and remove it,” said Woolard. “And you really can’t have someone sitting on the line looking into every bottle going past because they’d go mad, and we couldn’t afford it.”

The future: solving quality issues and increasing accuracy

With this setup, each bottle passes through at a rate of about 60 to 70 milliseconds. The sensor display screen also functions in another way: it enables multiple bottle pre-settings. “We run multiple bottles of all different shapes and sizes through the line as well, so if we ever need to change the bottle it’s as simple as a click and we can change of the settings on the screen,” said Woolard. “It’s that easy. The hardest part of the process was setting it up and adjusting it specifically to every bottle. But we had Tim to assist us, which was great.”

“What happened was it changed the way we looked at the process,” said Woolard. “Rather than looking for discoloration, we realized, ‘why don’t we look for a lack of color?’ From there, it was easier to highlight and find discolored bottles.”

Moving forwards, FPC is looking to increase the amount of SICK automated solutions in its system. “It’s an ongoing process to keep evolving,” said Woolard. “We’re looking at putting in other SICK units of a similar nature on other lines as well, to cover related quality issues and to help increase the accuracy that we have now.”

The benefits of working with SICK, as Woolard explained, was the locality offered despite having a large knowledge base overseas that SICK was able to tap into. “You can call them and say, ‘hey we’ve got this issue’, and they have the ability to come and assist in person,” said Woolard. “Besides their wealth of experience in the industry and knowledge of optical sensors, we know going to them would provide a fast and effective fix.”

Automation: the key to improve quality

Read more

Powerful image processing: for added quality and added efficiency

Non-stop ice cream on a stick

Identification solutions from SICK optimize meat processing at Goedegebuur

Procesamiento de imágenes 2D y 3D individual y fácil de configurar gracias a SICK AppSpace