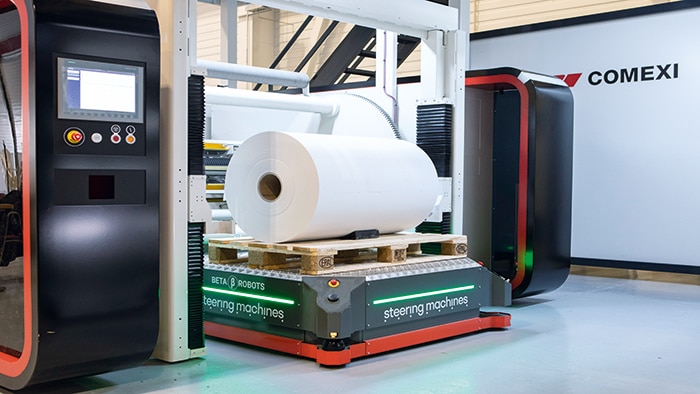

The automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) from Steering Machines significantly increase productivity in industrial environments –thanks to the help of SICK sensor solutions. The alliance between both companies has provided a rugged and safe solution the production chain of Comexi, a multinational company dedicated to the manufacturing and marketing of capital goods for the flexible packaging printing and converting industry.

Take a load off: optimize loading and displacement by autonomous mobile robots

The use of AGVs / AMRs for the development of tasks and movements in industrial environments is no longer just a trend, but now another part of the production chain. However, external elements are needed to allow these AGVs / AMRs to be safe without losing productivity.

AGVs and AMRs for loading and transportation in production plants and logistics centers

SICK offers optimal and safe operations of AGVs / AMRs in industrial environments. This is demonstrated by Barcelona start-up, Steering Machines, which is a developer of omnidirectional AGVs / AMRs for loading and transportation in production plants and logistics centers.

Steering Machines require sensors to obtain accurate and safe information about the movement, in context of speed and direction level, of its omnidirectional Moby AGVs / AMRs. To do this, they use the absolute and incremental safety encoder with SICK components, which quickly provides the reliable data with the important parameters.

This encoder stands out for being operational, being only one (instead of the usual two) and it is compatible with the safe speed controllers of the Flexi Soft MOC0 and MOC1 family. SICK's integral solution for Steering Machines is completed by the microScan3 safety laser scanner, a device with high resistance to dirt, dust, and the incidence of sunlight thanks to the innovative safeHDDM® (High Density Distance Measurement) scanning technology. The Flexi Soft safety controller offers optimized scalability for each application, depending on the complexity.

Successful application at Comexi

The combination of SICK and Steering Machines has been successful in the production chain of Comexi, a multinational company dedicated to the manufacturing and marketing of capital goods for the flexible packaging, printing, and converting industry. Comexi wanted to contribute to increasing the productivity of its customers with AGVs / AMRs by reducing the downtime between machines and other incidents, such as displacement in small environments or lack of material.

Thanks to the Moby AGVs/AMRs and the SICK methodology, they obtained the results they expected: “SICK and Steering Machines provided us a robust and safe final solution to minimize errors in our customers' production chain. The AGV / AMR allows them to move large loads without taking much space, which increases their efficiency,” explains Pedro Jiménez, Comexi's Digital Brand Manager.

“Our alliance with Steering Machines has served to provide the solutions that COMEXI was looking for. We have managed to generate security while, at the same time, improving productivity because of the solidity of our products,” assures Mikel Saez de Buruaga, Product Manager of SICK Spain.

“SICK sensors and solutions are the natural accompaniment to our products. In addition, it allows us to achieve a safety performance level d in movement, speed, and turn, following the current regulations for this type of application,” highlights Carles Domènech, CTO of Steering Machines.

Read more

The perfect size of the protective field on an industrial autonomous vehicle

The new mobility: How sensors control the cobots of the future

Modular and mobile – AGVs on the move providing maximum flexibility

Mobile robots:

Move into new dimensions

Robotics is on the move, whether it be in production, logistics or service. Sensor solutions for all variants of mobile robots

I want to stay up to date and regularly be informed about new articles!