One of the major issues associated with Industry 4.0 is making workflows flexible and that includes closer interaction between humans and machines. Part of this current move toward more integrated working is a need for humans and machines to work together safely, and in view of this, functional safety will take todays production systems one step closer to more flexibility. Human/robot collaboration (HRC) looks at how this can be achieved.

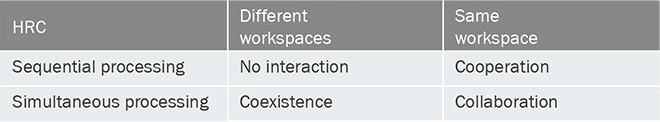

There are different forms of automation depending on how humans and machines work together. If the ultimate goal is complete collaboration - where humans and robots share the same workspace and carry out their work at the same time - then it makes sense to develop solutions that employ coexistence or cooperation as initial steps toward this. Doing this requires not only an in-depth understanding of robotics applications, but also expertise in assessing risks and access to the right portfolio of safety solutions.

SICK as a partner for HRC Solutions

Every process in developing HRC systems starts with a risk assessment. To conform to the Machinery Directive, an extensive assessment of possible hazards must be carried out for every machine as defined in EN ISO 12100. As robot systems have to complete motion sequences that are usually very complex, the robot safety standard EN ISO 10218 also requires that each motion sequence is analyzed in addition to hazards being assessed. Environmental factors and basic conditions associated with the HRC application must also be considered and documented in the risk assessment. These are absolutely essential steps in defining what form the appropriate safety measures should take. Creating solutions for the various safety measures required in human/robot collaborations incorporates a whole range of technology types and components, which have to work together as efficiently as possible and avoid any impact on the workflow - and thus on productivity. In response to this, SICK offers various harmonized safety solutions that make it possible to map the safety function in full, whether it is being retrofitted in existing plants or integrated into new ones. Not only that, but machine and plant manufacturers - as well as system integrators - are given consistent support when putting their protective measures in place, through access to SICKs extensive services. In this case, a plant walk-through is followed by the risk assessment of the .specific HRC solution and a safety concept tailored to suit the exact needs of the application is created. SICK also provides support for technical integration, machine acceptance, and documentation if required - and even includes regular checks in its range of services.

Find an overview of types and examples of human/robot collaboration here.

Find an overview of types and examples of human/robot collaboration here.