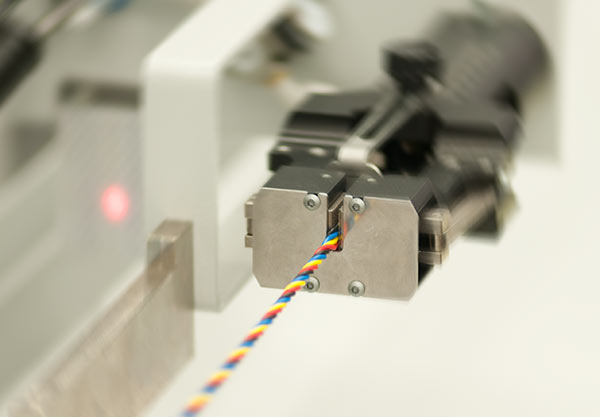

In semiautomatic cable twisters of the Komax Wire Company several wires were twisted into a more compact strand. Twisting has the benefit of preventing the transmission of interference pulses into the wires, e.g. in the case of airbag cables or bus systems. The DL50 Hi distance sensor makes sure that the correct cable lengths are used and that the length of the twisted wire can be monitored continuously.

Founded in 1975, the Komax Group based in Dierikon, Switzerland, is a globally positioned technology company that concentrates on markets in the area of automation. The corporate group operates production plants in Europe, North America, and Asia, generating sales of about 282 million Swiss francs in 2012. One of the core business segments is Komax Wire. A partner of the automotive supply industry, the company stands for innovative and high-quality solutions in wire processing. One example of this is the semiautomatic bt188 T twister used to twist several wires into a more compact strand. um halb?Twisting has the benefit of preventing the transmission of interference pulses into the wires, e.g. in the case of airbag cables or bus systems, explains Urs Mehri, who heads one of the Research & Development departments.

Wanted: Sensor solution for set-up aid and process monitoring

In order to guarantee correct manual clamping of the cables and to enable process monitoring of the semiautomatic machine, Komax Wire was searching for a solution that simultaneously takes on the tasks of set-up aid, plausibility checking, and position monitoring during twisting. Following analysis of the task required, SICK recommended the DL50 Hi distance sensor. It meets all of the requirements related to measurement and interface technology.

DL50 Hi: mid-range all-rounder with compact housing

The DL50 Hi suggests itself as a true all-round talent: Featuring a long range, the sensor is well prepared for various distances, and thanks to its compact design, one can conveniently install and commission the device even in highly inaccessible places. Urs Mehri gives another decisive argument for Komax Wire: With its RS422 interface, the DL50 Hi fits perfectly into the control system of the semiautomatic twister, which enabled us to avoid the corresponding adjustment effort.

The sensor provides valuable assistance when clamping the wires. The semiautomatic twister consists of a firmly fixed twisting unit and a sliding frame that is mounted freely movable on a rail. Depending on the cable length, the sliding frame, fitted with a reflective foil, is positioned manually relative to the twisting unit at the distance specified by the controller. During this operation, the DL50 Hi carries out a plausibility check in order to avoid the clamping of wires featuring the incorrect length. Since the length of the twisted wire shortens, the sliding frame reduces its distance to the twisting unit over the course of the process. While this occurs, the distance sensor measures the distance every 2.5 ms, ensuring the necessary twisting and thus guaranteeing the desired cable length as well as the highest quality.

- Product information: DL50 Hi mid range distance sensors

- Product portfolio: Mid range distance sensors, catalog distance sensors

- Customer information: Komax Wire